Change Language :

Components for vertical farming

Lightweight, lubrication-free, cost-effective

Applications in vertical farming

Other relevant products

Lightweight and resistant to moisture

- 42% lower inertia and 48% lighter than comparable metal bearings

- Self-lubricating and maintenance-free

Drive axis for over 30m travel

- Modular system

- Driven by gear racks or toothed belts

- Available as a complete system with carriages, motors and control system

Set up in under an hour

- AMR for around €30,000

- Includes integrated fleet management

- Can be loaded with 50kg and pull up to 100kg

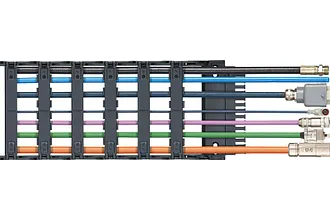

Supplied ready with connector

- Designed for the requirements in SRU

- Over 1,300 control, motor, data cables and more

- UL-certified and with a 4-year guarantee

Highly resilient and low-maintenance

- Available as V-, L- and U-profiles

- Lightweight

- Different materials available

From a batch size of 1 to high-volume production

- Longer service life than gears made from commercially available plastics

- Free from lubrication and maintenance

PTFE-free and FDA-compliant

- Free from lubrication and maintenance

- Predictable service life

- More than 10,000 installation sizes

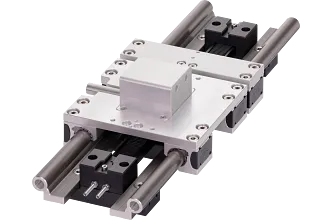

Automatic format adjustments

- Manual or motorised drive possible

- Flexible and repeatable adjustment of lane width

Advantages of vertical farming ...

- Saves space by freeing up areas of conventional farmland

- All-season harvesting, independent and flexible

- Low transport and storage costs

- Saves water due to closed cycles

... with the advantages of our motion plastics

- No external lubrication, no maintenance, no contamination of the products

- Resistant to dirt and dust

- Corrosion-free and FDA-compliant

- Fast ROI thanks to cost-effective automation components

Success stories

Tested for real use in the test laboratory

All products are tested for wear and load capacity under real conditions in the igus test laboratory, the largest in the industry. The results are used as a basis for our tools that calculate service life and allow for precise predictions about durability.

Upon request, igus also carries out customer tests under very individual conditions.

Other agricultural sectors

Consulting

I look forward to answering your questions

André Schönhaar+49 2203 9649 8316Write e-mail

Shipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Friday: 8 am – 5 pm