Change Language :

Cable strain relief

Safe ✔ Durable ✔ Reliable ✔

What types of strain relief does igus offer?

Why is cable strain relief important?

A strain relief is a mechanical device that prevents tensile forces from acting uncontrollably on cable connections. Strain relief is particularly important in dynamic or heavily stressed applications to prevent damage such as cable breakage or vibrations and shocks.

The right strain relief offers several decisive advantages:

Increased service life of the cables: reduction of mechanical stress and prevention of cable breaks

Greater operational reliability: fewer breakdowns due to damaged cables

Economic efficiency: fewer cable breaks and failures significantly reduce repair and maintenance costs

Better performance: cables can work more trouble-free, even with long and intensive mechanical use

How does a strain relief work?

A cable feed-through with strain relief fixes the cable in the cable gland or in the plug-in connector. The strain relief ensures that external forces are not transferred to the cable, but are absorbed by the structure on which the strain relief is assembled.

The forces at the contacts in the connector or in the cable are then zero. No matter how much the cable moves on the outside, it is at rest on the inside. This protects the contacts and sensitive electronics.

What needs to be considered for strain relief?

To ensure the optimum performance of energy chains, the following criteria should be taken into account:

- Cable type and diameter: Flexible cables require different fastenings than thick cables

- Movement profile of the energy chain: High speed or tight bend radius influence the requirements

- Environmental conditions: Temperature, humidity and chemical load must be considered

- Assembly requirements: Quick maintenance or modularity are often decisive

Why use strain relief from igus?

igus has established itself as a leading supplier of energy chains and accessories and offers numerous unique selling points that play a decisive role in the choice of strain relief for cables in energy chains. Here are the main reasons why strain reliefs from igus are the better choice for many applications.

- Customised for energy chains

- Cable-friendly design

- Many years of experience and expertise

- Comprehensive testing

- Large selection of strain reliefs for energy chains

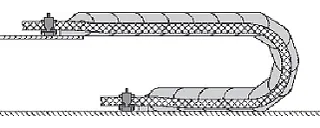

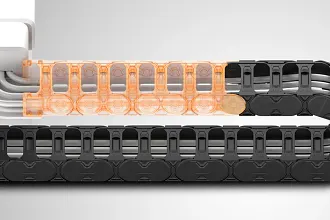

Minimum gap between the strain relief and the beginning of the bend radius

A series of in-house tests have shown that a small distance between the strain relief and the bend in the energy chain has no negative impact on the durability of chainflex cables. It is therefore possible to integrate a strain relief for cables directly into the mounting bracket. We offer strain relief options, e.g. the chainfix clamp or the space-saving tiewrap plates for almost all energy chains.

Practical testing taking into account a wide range of parameters

igus strain reliefs are tested in our in-house igus laboratory under the influence of fluids such as water or oil at various ambient temperatures, taking a wide range of parameters into account. The interaction of the strain reliefs with the various jacket materials, cables and hoses, of course, also plays a role in the in-house tests

Catalogue. For more information, see the strain reliefs catalogue.

Download now (PDF)

Energy chains shop. From small to medium and large energy chains for all applications.

To the shop

Energy chain configurator. Design energy chains quickly and easily.

To the energy chain configurator

Energy chains wiki Find all the most important information as well as questions and answers about energy chains.

To the energy chain wikiConsulting

I look forward to answering your questions

Dieter Reitz+49 2203 9649 7070Write e-mail

Shipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Friday: 8 am – 5 pm