Change Language :

3D printing wiki

Technical information about 3D printing at igus

Learn how you can successfully use additive manufacturing with wear-resistant plastic to increase the service life of your applications and reduce production costs. On this page, our 3D printing experts share their expertise on the topics of design, material selection and manufacturing for industrial requirements.

Tips and things worth knowing about 3D printing

Rapid prototyping: The path to rapid product development

With rapid prototyping, product ideas can be turned into the first tangible prototypes in the shortest possible time. Various manufacturing processes such as 3D printing, CNC machining and other technologies are used. Discover how we can work with you to shorten development times and quickly turn your ideas into reality.

FDM printing: Layer by layer to the finished component

In FDM printing, plastic filament is heated and applied layer by layer. Small parts can be produced quickly and cost-effectively. Read more about how the process works, advantages and limitations, processing tips and practical examples from industry.

Food-safe 3D printing with filament

Not all materials are suitable for contact with food. So what requirements apply to components in contact with food and how can they be implemented? Find out more about standards and norms such as FDA and EU 10/2011, material selection and practical tips for processing filaments that are food-safe.

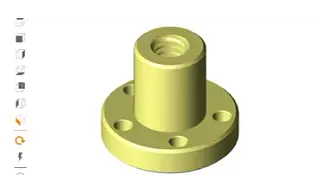

Design special lead screw nuts for 3D printing

The production of complex special nuts often involves a great deal of manual effort, which can quickly make such solutions very expensive. In this case, 3D printing technologies help reduce costs - but they also require a 3D model of the desired thread. You can find out how to create CAD models for special nuts in this article.

Design tips: multi-material components from the 3D printer

When using filaments for 3D printing, components can be produced from two or more materials. There are a few things to consider when designing such components digitally with CAD programs. For example, how do you ensure that the different materials overlap smoothly in the same component? You can find answers to this and other questions in this article.

How do I replace my defective gear?

Machine downtime due to a defective gear in the gearbox is extremely inconvenient. The gear should be replaced immediately. In such a case, the 3D printing service from igus offers a fast and reliable replacement option. How do you get a new, wear-resistant gear from 3D printing step by step and without CAD knowledge?

How do I use the igus bonding agent for tribofilaments?

Especially with demanding filaments, it can happen that the component does not adhere properly to the print bed. As a result, the corners of the component can separate from the print bed, leading to undesirable deformations. In the worst case, the component can even become completely detached from the print bed. Solve this problem now with the igus® bonding agent!

Free e-papers and downloads

Guide to 3D printing with filament

This guide provides 24 tips for 3D printing with filament to help you easily avoid common printing problems.

Download guide

Guide to 3D printing with resin

This guide shows how to avoid common printing problems when processing resin.

Download guide

3D printing design guide

Design guide for components manufactured via the 3D printing service, including practical tips that help extend service life.

Download the design guide

Design guide for resin components

This design guide provides useful tips for designing components for 3D printing with resin in order to avoid printing errors.

Download the design guide

Guide for 3D printing of gears

In this guide, you can find out everything about the three most common mistakes made when printing gears in 3D, and how to avoid.

Download guide

3D printing materials compared with POM

Are 3D printing materials a viable alternative to POM? This white paper provides technical data, test results and practical examples.

Download white paperOn-demand webinars and live streams

How do you successfully process filaments in your own 3D printer?

Development engineer Niklas Eutebach shares his practical knowledge of 3D printing with filament and gives tips on material selection, processing and reworking.

Which igus tribofilament is the right one for my application?

In addition to tips on material selection, the in-house processing of filaments is compared with ordering components from the 3D printing service.

Multi-material 3D printing for intelligent or extremely rigid components

Would you like to combine the advantages of different materials in one component? Then discover the creative possibilities igus offers!

Food conformity with wear-resistant components - what is possible?

Find out more about igus' materials, 3D printing processes and reworking options for the food industry.

Why print gears in 3D instead of milling them?

What are the advantages of 3D-printed gears over milled gears? Find out how you can quickly design your 3D gear with the igus CAD configurator.

Three common mistakes when 3D printing gears

Avoid the mistakes mentioned in the webinar to maximise the benefits of 3D-printed plastic gears in industrial applications.

3D printing of gears: faster to series production thanks to service life calculation

With the help of the igus gear service life calculator, you can significantly reduce trial periods and testing times. Find out here how this online tool works.

Additive manufacturing in series production: Five application examples with "cost down, life up"

With 3D-printed components made from igus plastics, you can reduce costs and increase service life. Which applications offer great potential for this?

Design data for printer construction

Build your own large-scale 3D printer and print components or up to 1m in size.

To the data

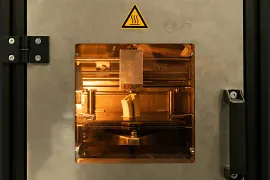

A high-temperature 3D printer can be very expensive! Save money and build your own one now.

To the data

Wear test results

Our 3D printing materials are tested for wear resistance and robustness in our in-house igus test laboratory.

To the test results

Frequently asked questions about 3D printing

The most common customer questions about 3D printing services and the specification of 3D printing materials from igus.

To the 3D printing FAQDo you have any questions or suggestions or are you interested in workshops and learning material on specific topics? Please don't hesitate to write to us!

Consulting

I look forward to answering your questions

Shipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Friday: 8 am – 5 pm