Change Language :

System availability has never been as affordable as it is today | i.Sense EC.W

New low cost service life sensor enables cost-effective real-time condition monitoring with integrated potential output for direct machine connection for gliding e-chain systems from € 248.00 (DE list).

IoT expert Richard Habering explains the use and benefits of the new low-cost i.Sense EC.W service life sensor:

i.Sense EC.P - intelligent push/pull force monitoring successfully implemented

When do I need a smart condition monitoring system like i.Sense EC.P?

When regular maintenance work requires complete production shutdown ...

When motion anomalies cannot be detected by humans in time ...

If plants or machines need to be monitored frequently or continuously ...

If energy supply system travels are difficult to access or view ...

If maintenance work poses a health or safety risk ...

If maintenance costs are to be reduced and service life extended ...

Integration into your own network environment

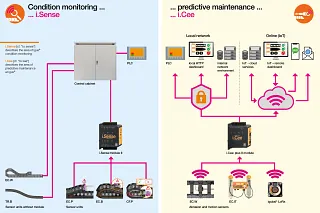

As part of the i.Sense condition monitoring system from smart plastics, all data from the new EC.W sensor can also be analysed in the i.Cee control cabinet module. This can then be used to digitally control the entire alarm and escalation management of the system.

The i.Cee module can also be integrated into predictive maintenance concepts in a number of ways. From preventive service management, which schedules regular maintenance depending on use, to location-independent fault management, which immediately reports any unforeseen change via various mobile channels. All information is collated in a modern dashboard, online or offline in the local network, depending on the customer's requirements.

Overview of smart plastics

Overview of the complete igus product range for Industry 4.0

Contents of this brochure:

- Condition monitoring (i.Sense)

- Systems for condition monitoring

- Advantages of condition-monitoring systems

- Application examples of condition monitoring

- Predictive maintenance (i.Cee)

- Systems for predictive maintenance

- Advantages of predictive-maintenance systems

- Application examples for predictive maintenance

- Data flow in modern smart-factory concepts

Consulting

I look forward to answering your questions

Shipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Friday: 8 am – 5 pm