Change Language :

Smart maintenance solutions for energy chain systems and bearing technology from igus

Prevent downtimes ... extend product operating times ... save maintenance costs ...

with smart plastics

With i.Sense continuous condition monitoring, you can keep an eye on your systems at all times. With i.Cee, you can connect your production system to the Internet of Things (IoT) or your local network and have the option of predictive maintenance.

With smart plastics - energy chain systems, chainflex cables, linear guides and plain bearings equipped with smart sensors - we are pursuing the goal of making complex automation solutions as Industry 4.0-capable as possible.

What you would like to know about smart maintenance:

Condition monitoring + predictive maintenance = smart maintenance

The key to success: smart maintenance offers a wide range of options for making applications as simple as possible and as smart as desired.

These igus products can be equipped with smart plastics technology

Smart maintenance: examples from the industries

Knowledge Base

Applications with smart plastics

Bread packaging machine

Bread packaging machine:

Avoid cable breaks with smart plastics

Smart prevention of cable breaks

Sensor system monitors energy chains in engine plant in the automotive industry

The Austrian automotive supplier therefore relies on smart plastics from igus® to avoid unplanned failures and plant downtimes.

Smart maintenance in the automotive industry

Predictive maintenance in train wash systems

The full smart plastics package, which optimally combines condition monitoring and predictive maintenance

Predictive maintenance in train-washing stations

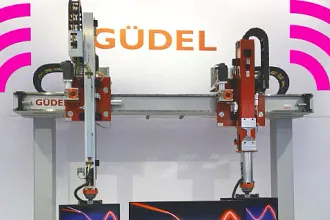

Güdel relies on condition monitoring for the energy chain on linear robots

Güdel avoids breakdowns on its linear robots thanks to real-time measurement of movement, temperature and wear in the energy chain.

Güdel relies on condition monitoring for the energy chains on linear robots

Condition monitoring in wastewater treatment plants

smart plastics prevent the plant from being stopped in the event of a malfunction to prevent expensive consequential damage

Condition monitoring in the sewage treatment plant3D CAD portal for smart plastics

Designing intelligent energy chain systems faster. CAD models for all smart components.

Our intelligent e-chain systems are already being used reliably in many hundreds of thousands of applications worldwide - from beverage vending machines and CNC machines to steelworks. Unsupported lengths can be bridged with ease and long travels are conceivable for a wide range of industries.

Further information material:

smart plastics catalogue

Always the latest PDF catalogue online for download:

Tested!

Over 3,000 tests are carried out every year to collect sufficient data for the service life algorithm.

Recycling program

Energy chains, regardless of the manufacturer, can be recycled at igus. How does it work?

Online seminar

Benefit from the experience of our experts:

Interactive✓ informative✓ free of charge✓

Consulting

I look forward to answering your questions

Shipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Friday: 8 am – 5 pm