Change Language :

FDA compliant and maintenance-free: components for beverage production

Use of igus products in beverage technology

Selected products for the beverage technology

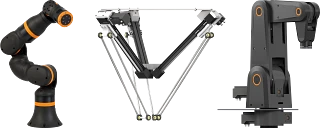

Cobots, delta pickers, articulated arm robots and much more ...

Automation in the packaging industry

Automating processes with low complexity, fast integration into existing systems and a quick return on investment? That is the stated aim of our products from "Low Cost Automation".

Lane adjustment in the beverage industry - from manual to smart positioning

White paper: Colsterisation and tribopolymers

Especially in an industry that depends on precise and fast processing with maximum cleanliness and economy, the combination of colsterisation and high-performance plastics should become the standard ...

Customer application examples

More information

The large sample box

With the igus Corner, you always have the right motion plastics for your industry at your fingertips.

igus blogs

Topics and trends from the packaging industry. Discover them now in our blog.

Consulting

I look forward to answering your questions

Bastian Mehr+49 2203 9698 140Write e-mail

Shipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Friday: 8 am – 5 pm