Change Language :

Resistant to dirt, dust, and swarf: products for the woodworking industry

Find product solutions easily according to application type

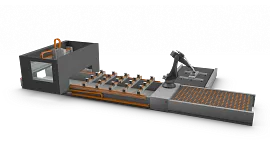

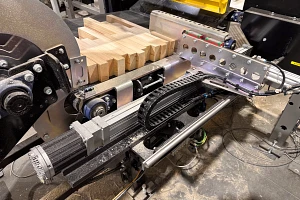

motion plastics for moving applications help reduce logistics, installation and throughput times. In woodworking machines and CNC machining centres, our energy supply systems ensure the controlled movement of cables and hydraulic and pneumatic hoses even under adverse conditions involving dust and swarf. Our linear guides and plain and ball bearings also require no external lubrication or maintenance. This makes them ideal for the woodworking industry since swarf, dust, and dirt cannot adhere to the bearing points thanks to dry operation.

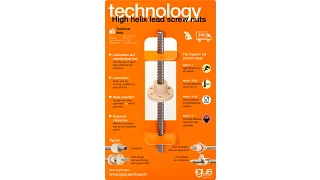

dryspin® lead screw technology sample

► For format adjustments and positioning tasks

► Free from lubrication and maintenance

► Higher efficiency

► Longer service life due to asymmetry

► Media-resistant

► Low-noise, vibration-free operation due to thread geometry

► Service life predictable online

Success stories

You might also be interested in

Recycling made easy

Energy supply systems, regardless of the manufacturer, or other industrial plastics: the chainge platform makes the circular economy easy.

We will come to you

View all motion plastics conveniently on your premises, either as a presentation in the office or in a show truck outside. Anything is possible.

Consulting

I look forward to answering your questions

Markus Kogelmann+49 2203 9649 7704Write e-mail

Shipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Friday: 8 am – 5 pm