Change Language :

Robots for schools, colleges and universities

Practical robotics training

The rapid development of digitalisation is fundamentally changing production processes and therefore requires new skills and competencies. It is therefore important that the specialists and managers of tomorrow are prepared for the new challenges. This is precisely where the Low Cost Automation training programme comes in:

- Practical relevance guaranteed: The robots developed and produced by igus® for the industry are used in the training courses. This ensures a seamless introduction to industrial robotics.

- Safety: igus® products are CE-compliant and therefore fulfil applicable safety standards.

- Cost-effective solutions: Whether individual components to build yourself or complete systems - customise the scope of the solution to your requirements.

Transparent prices and robot selection at a glance

The information brochure for educational institutions

Further information on prices and robot designs specifically for the education sector can be found in our information brochure.

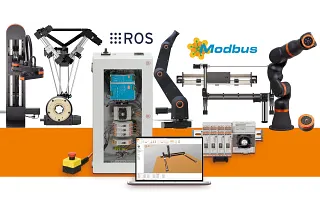

Sample programmes for your igus® Robot Control

Save time and money with our sample programmes

Faster integration of igus® Robot Control for your machines by combining simple modules and the igus® sample programmes.

- Free download programme

- Shortened integration time

- e.g. to LabView, ifm, ROS, Modbus, Matlab Simulink

- Compatible with industrial manufacturers (Siemens, Beckhoff, Wago, etc.)

Consulting

I look forward to answering your questions

Shipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Friday: 8 am – 5 pm