Change Language :

Application examples with smart plastics

Smart customer references with energy supply systems

Smart customer references from bearing technology

An overview of all industries

Selected highlights:

Agricultural engineering

Condition monitoring for high loads

Which smart plastics technology is used?

Wear coupling with integrated sensor for condition monitoring.

Why is it used?

The intelligent trailer coupling enables the customer to plan upcoming maintenance. Failures are avoided as the customer is informed in good time when a replacement is due. Expensive breakdowns or damage can thus be avoided.

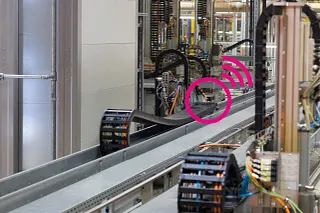

Automotive industry

Condition monitoring at the automotive supplier

Which smart plastics technology is used?

EC.B sensor for breakage monitoring + EC.W for measuring the abrasion of the energy chains.

Why is it used?

It is important to the customer that consequential damage to the system is avoided in the event of a chain breakage. The EC.B module recognises a break in the energy chain and switches off the system or at least issues a fault message. The EC.W sensor is used to measure the wear on the e-chains, which makes maintenance plannable

Smart breakage monitoring in 22 tonne automotive driving simulator

Which smart plastics technology is used?

P4.1 Energy guiding chains including intelligent breakage monitoring i.Sense EC.B

Why is it used?

Increased plant safety and availability; complete project realisation from a single source; smart early warning system

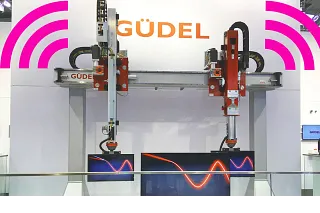

Gantries and linear robots

Smart maintenance planning on the linear robot

Which smart plastics technology is used?

EC.M sensor for the movement data and EC.W sensor for measuring abrasion on the energy chain

Why is it used?

The two sensors transmit the measured values via the i.com module (now i.Cee module) directly to Güdel's condition monitoring system, which analyses the data and thus makes it possible to plan maintenance.

Port Cranes

Complete smart plastics package on RMG crane

Which smart plastics technology is used?

Condition monitoring: EC.P to determine the push/pull forces, EC.B to determine chain breaks, CF.P to measure the tensile force on cables, EC.M sensor for the movement data and EC.W sensor to measure the wear on the energy chain.

Predictive maintenance: i.Cee.local

Why is it used?

For maximum system protection, overview, maintenance management, product service life and safety.

Smart shipyard crane: reliable despite typhoon storms

Which smart plastics technology is used?

Roller energy chains with the i.Sense EC.P push/pull force detection system that monitors the displacement forces of the energy chains online.

Why is it used?

To prevent damage to the system and failures due to preventive maintenance or remote intervention.

12 Ship-to-shore cranes with smart heavy-duty energy chains

Which smart plastics technology is used?

E4/4 heavy-duty energy chains with smart i.Sense condition monitoring system

Why is it used?

Due to the demanding application environment to prevent damage and downtime

Robust and smart - How digitally networked energy chains strengthen STS cranes in the port of Rotterdam

Free case study for download

This case study clearly describes how EMO B.V. was able to achieve mileages of over 375,000 km on its STS cranes with igus chains for cranes®.

100% trust in i.Sense monitoring in the port of Haifa

Which smart plastics technology is used?

Complete i.Sense condition monitoring system for existing 4040HD energy chain

Why is it used?

Extension of service intervals and thus significant cost savings while reducing the risk of failure

Overview of smart plastics

Our new brochure shows you everything at a glance

Topic overview:

- Condition monitoring (i.Sense)

- Condition monitoring products

- Application examples of condition monitoring

- Predictive maintenance (i.Cee)

- Application examples for predictive maintenance

- How does the data flow with predictive maintenance?

Indoor cranes

Complete overhead crane automation thanks to i.Sense

Which smart plastics technology is used?

Complete smart plastics package with i.Sense - Condition Monitoring and i.Cee - Predictive Maintenance

Why is it used?

Real-time monitoring of the status of the energy supply system of the automated crane and a significant reduction in the risk of failure

Predictive maintenance in upholstery factory

Which smart plastics technology is used?

E4 series energy chains with i.Cee for predictive maintenance

Why is it used?

Maximum availability and maintenance recommendations before unplanned downtime occurs. The result: over 15 years of continuous operation

Intralogistics: Avoid downtime in the warehouse

Warehousing without interrupting logistics is essential for fast supply chains. Customers do not want to wait unnecessarily for their goods, while timely delivery is a decisive competitive advantage for manufacturers. The processes run largely automatically, especially with large-scale intralogistics. Not only smart plastics, but also our energy chains, cables, plain and linear bearings can help here.

Reducing costs with smart e-chains in waste cranes

Which smart plastics technology is used?

Completely pre-assembled readychain system with i.Sense tension and thrust force monitoring

Why is it used?

Additional safety is provided by an i.Sense push/pull force measurement system that monitors the entire system and switches off the crane in the event of an overload. This prevents damage to the chain and cables and therefore costly breakdowns before they can occur.

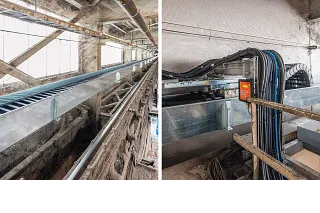

Sewage and wastewater treatment plants

24/7 emergency monitoring in the sewage treatment plant

Which smart plastics technology is used?

EC.P tensile force monitoring on the energy chain

Why is it used?

The tank scrapers in sewage treatment plants run slowly but 24/7 and damage to the system may only be recognised hours later. In order to stop the system in an emergency, the EC.P module is used in many sewage treatment plants with energy chain, which stops the system in an emergency so that the damage can be repaired and expensive total damage can be avoided.

Composting and incineration plants

Save 60% water with intelligent precision casting trolley

Which smart plastics technology is used?

Reliable energy management system with intelligent i.Sense EC.P system

Why is it used?

Amortisation within 4 years and avoidance of major damage and cost-intensive repairs to the pipework

Smart Move: Rolling instead of dragging on the bunker crane

Which smart plastics technology is used?

"Heavy duty" roller energy chain with included i.Sense condition monitoring system

Why is it used?

Intelligent and reliable energy and signal supply in the most adverse environmental conditions

Bulk handling

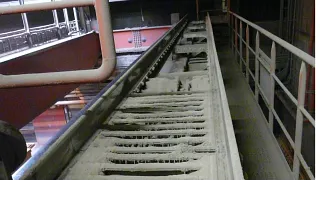

Safe bulk material conveying with sensor-equipped energy chain

Which smart plastics technology is used?

i.Sense EC.P for permanent monitoring of the prevailing push/pull forces

Why is it used?

In order to provide additional planning reliability for such dimensions, the entire cable routing is supplemented by smart plastics, i.e. intelligent sensor technology in combination with energy chains. Damage to the cable routing can thus be prevented before it occurs.

Smart push/pull force monitoring as a dirt detector

Which smart plastics technology is used?

i.Sense EC.P as a cleaning reminder for the system

Why is it used?

"If the movement of the chain is obstructed too much by dust and dirt, the push/pull force monitoring switches off the system before damage occurs and we know that it is time to clean the chain's travel path again."

Longest travel with intelligent roller chain system

Which smart plastics technology is used?

i.Sense EC.P for permanent monitoring of the system

Why is it used?

The system includes an intelligent sensor system for monitoring the push/pull forces, which can be used for an emergency shutdown in the event of increased forces.

615m travel distance with continuous condition monitoring

Which smart plastics technology is used?

Roller e-chain type 5050RHD with i.Sense Condition Monitoring System

Why is it used?

Problem-free operation without failure for more than 10 years

Packaging machines

Washing systems

Predictive operation without surprises: smart energy chains for Europe's most modern train wash system

Free case study

In this case study, we talk about how CFL, Luxembourg's national railway company, uses several energy chains from igus® together with intelligent sensor technology from smart plastics to overcome numerous challenges:

- How exactly are failures prevented?

- Which components were to blame for the failure?

- How and with which tools was the entire project approached?

- And how is it currently going?

Smart plain bearings

Do you want to put together your own smart plastics package?

Then download the digital version of our smart plastics Domino now and put together your very own configuration.

You can then look forward to a playful gift from smart plastics.

Consulting

I look forward to answering your questions

Shipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Friday: 8 am – 5 pm