Change Language :

Building automation systems: Simple, modular, flexibly expandable

drygear® Apiro modular gearbox system

Individual applications can be realised extremely modularly and cost-effectively with the drygear® Apiro modular gearbox system. Possible applications can be in the packaging, food and medical industries and many more, e.g.

- lane adjustment,

- pusher tasks,

- gearboxes with different ratios,

- slewing rings and rotary axes

20 application examples for the modular gearbox system

iDeas templates for easy replication

The Apiro® modular gearbox system is now available with 20 iDeas templates, making it easy to build your own superstructures.

To the finished gearbox in three steps

1. Select automation solution

2. Download parts lists and CAD data

3. Simply replicate the automation solution

Apiro® starter kit

1 Robot gearbox construction kit for eight systems

The robot modular gearbox system Apiro® (Greek for "infinite") is now available as a starter kit. Instructions help you to assemble your own robot.

Tech up

- Application examples from the drygear Apiro modular gearbox system

- Tips on superstructures up to incl. parts lists

- Extensive selection aid for application implementation

Cost down

- Cost-effective gearboxes made of iglidur® polymer material

- Modular design for manual and motor-operated adjustments

- Fast conversion possible

Proof

- Worm gears made of tribologically optimised igus high-performance polymers

- 40% better performance through iglidur® A180

Sustainability

- Modular design enables rapid expansion, conversion and adaptation

- Very light and completely lubrication-free

- Recyclable materials

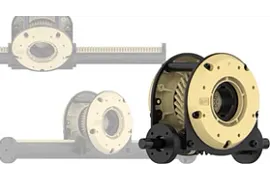

Gearbox with drive pin

The standard version among the Apiro gearboxes: the gearbox with drive pin enables a direct drive connection. Available ratios are: 4:1, 32:1, 64:1, optionally also: 3:1, 5:1, 8:1, 16:1

To the shop

Gearbox with multifunctional profile

The multifunctional profile can be used to realise series connections of gearboxes, as distances between elements or products can be regulated. This combination is often used for applications in the food or packaging industry.

To the shop

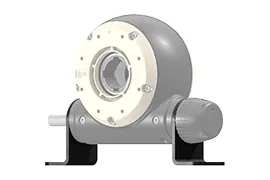

Bevel gearboxes

Bevel gearboxes are used wherever movements and forces have to be transmitted at right angles. With a 1:1 ratio, the transmitted torques can be transferred almost loss-free.

To the shop

Hygienic design gearbox

The Apiro gearbox in HD prevents contamination during production and enables simple and safe cleaning. Typical application areas: Food industry, pharmaceutical industry, etc.

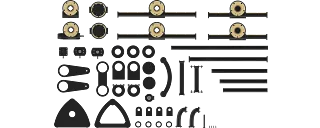

Accessories

The drygear Apiro accessories enable various installation options for vertical and axially horizontal movements, as well as profile stop-dogs.

To the shop

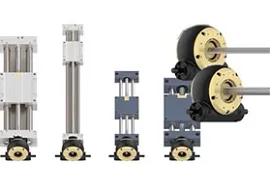

Connection to the output of drive and lead screw technology

With the new connection to drylin drive technology and dryspin lead screw technology, you are now even more flexible in the realisation of individual automation systems.

drygear® Apiro - Tested and proven

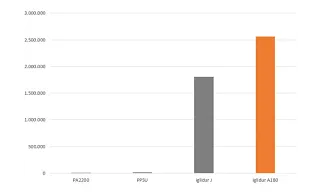

40% better performance thanks to iglidur® A180

Service life in cycles: Apiro worm gear made from iglidur® A180 on aluminium h.c.

i=32, 20RPM at 3.5Nm

Continuous quality testing in our in-house test laboratory - also for customer applications We are also happy to test your application in order to better assess application scenarios.

Send us your request

1. Describe your individual application The modular gearbox system enables a wide range of automation applications with simple and complex motion sequences.

2. We select the optimum components for you Our experts will find the ideal solution for you with as few components as possible.

3. Simple assembly The modular gearbox system has a modular design so that different kinematics can be implemented by simply plugging them together

Assembly instructions for download

The gearboxes and components at a glance

Gearbox with turntable

This gearbox is particularly suitable for slewing ring applications, as it can be used as a rotary axis, among other things. For example, it can be used in laboratory automation.

To the shop

Gearbox with coupling

The coupling can be used to attach various shafts with a maximum diameter of 12 millimetres. An application example is the adaptation to linear axis.

To the shop

Cantilever axis

The linear drive enables various strokes in the application. Gear rack elements included. Configurable in various lengths, for example for slider applications.

Optionally available with an integrated planetary gearbox.

To the shop

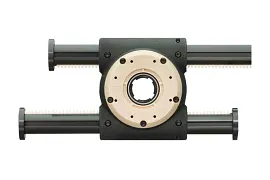

Cantilever axis with double axis

The cantilever axis from the Apiro® modular gearbox system is now available with a double cantilever axis. Suitable for motorised or manual drive. The modules can be used in series or in parallel with stroke from 60 - 1,050mm.

To the shop

Consulting

I look forward to answering your questions

Steffen Schack

Head of Business Unit drygear® Gears and Gearbox Technology

+49 2203 9649-9827Write e-mailShipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Friday: 8 am – 5 pm