After selection of your ZIP code, we designate the relevant staff to attend to you at once.

After selection of your ZIP code, we designate the relevant staff to attend to you at once.

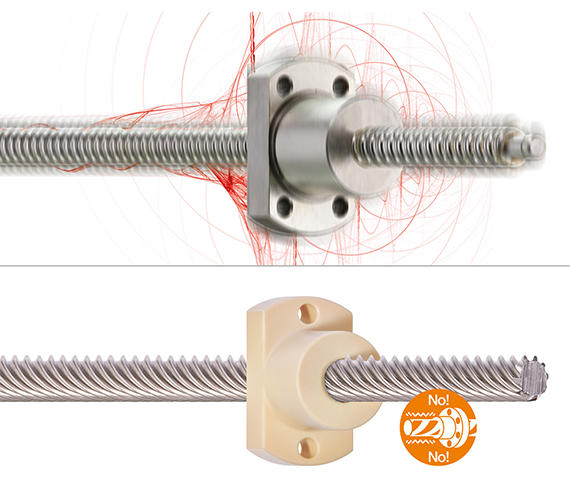

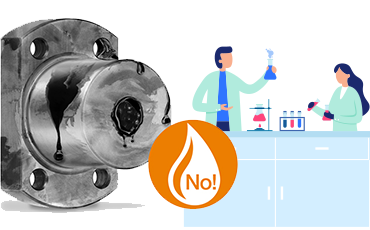

In medical technology, metallic lead screw nuts continue to be the norm. However, they mostly require frequent maintenance and lubrication. In this process, dust and dirt particles can easily stick to the used lubrication. This leads to considerable contamination and a significantly higher wear compared to a system that works in dry operation. Furthermore, the metallic lead screw nuts can corrode quickly in humid environments.

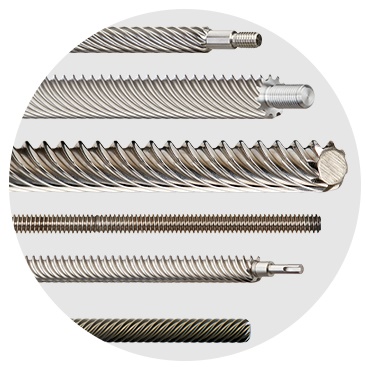

The lubrication-free and maintenance-free drylin lead screw technology is used in medical technology and convinces due to its many advantages. It is absolutely free from lubrication and maintenance and can also be used in corrosive environments without problems.