After selection of your ZIP code, we designate the relevant staff to attend to you at once.

After selection of your ZIP code, we designate the relevant staff to attend to you at once.

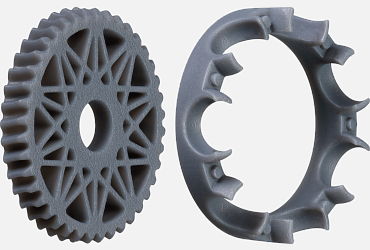

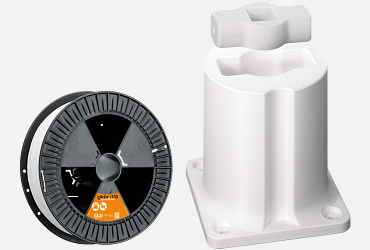

The highlight at our trade show stand was iglidur i230. The slide-optimised laser sintering material is PFAS-safe with improved mechanical strength and withstands application temperatures of up to 110°C. Due to the wide range of electrical-engineering applications, we also developed the new iglidur i9-ESD laser sintering powder for sensitive electronic components.

The igus 3D printing team is already looking forward to meeting you again at the next Formnext and to presenting our innovations for industrial 3D printing.

See you next time at Formnext 2024!

Monday to Friday from 7 am - 8 pm.Saturdays from 8 am- 12 pm.

24h