Change Language :

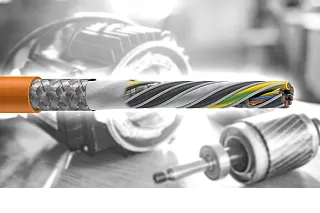

Hybrid cable for the energy chain

Hybrid cables on drive units constitute a relatively new trend and generally involve a combination of energy cores, supply cores for brakes and temperature sensors and a bus system. The bus system serves to transmit digital information from the encoder integrated in the motor back to the frequency converter. This eliminates the need for an additional encoder cable and the associated costs and room for cable and connector.

Differences between manufacturers

Hybrid technology is the biggest trend in the cable industry in recent years and is also known as One Cable Connection (Siemens) or One Cable Technology (Beckhoff). With this technology, four power cores (L1, L2, L3 & PE), a pair e.g. for temperature monitoring and cores for a bus system are usually combined in one cable. Each major drive manufacturer uses its own bus system; Beckhoff, for example, uses the Hiperface DSL bus system from SICK, while Siemens uses an Ethernet derivative. We at igus have followed this technological trend and optimised the mechanical cable design for the energy chain. Our hybrid cables CF220.UL.H and CF280.UL.H can be easily connected to the drive systems of the major OEMs.

What are the advantages and disadvantages of hybrid cables?

Two cables are required for each drive - motor and encoder cable. By combining them in one cable, space is created in the energy chain and also in the connection area of the motor, as half of the components are eliminated. Interference caused by the proximity of sensitive data cores to energy cores should be avoided wherever possible. The good electromagnetic compatibility specifications of the shields in the cable and a good connector concept can provide a remedy here. We achieve the good shielding effect through a high coverage of the necessary elements and a flat braid angle, which ensures that the specifications are maintained for a long time even during movement.

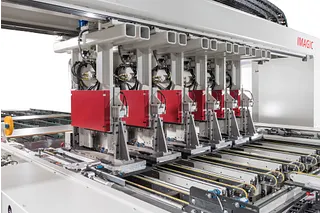

Hybrid cables in woodworking

A major manufacturer of woodworking machines has transferred its drive technology to a new hybrid technology from Beckhoff and thus utilised all the advantages of the more compact type. The challenge arose with the cables, which have to perform an extremely large number of movements in very small radii on their machines. This is where igus came into the race with a demanding endurance test for service life. Challenging because the data transmission of the Hiperface DSL bus also had to be measured during use. We therefore worked very closely with our customer to achieve reliable results for both sides. Please feel free to contact us if you are interested in permanent cable solutions that need to be tested.

Do you already know our online tool?

Easy to find, select the right type, calculate service life and order online

Product finder

Find exactly the right cable quickly

Service life calculator

Calculate the service life of any chainflex cable

Copper surcharge calculator

Calculate the daily copper surcharge

Configurator for customised cables

Configure your customised cable in just 3 minutes

Are you still looking for an energy chain for your cable?

To the energy chains

... or everything already harnessed?

To the readychainConsulting

I look forward to answering your questions

Nils Jäger+49 2203 9649 9823Write e-mail

Shipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Friday: 8 am – 5 pm