After selection of your ZIP code, we designate the relevant staff to attend to you at once.

After selection of your ZIP code, we designate the relevant staff to attend to you at once.

Individual applications can be implemented with the drygear® Apiro modular gearbox system in a modular and cost-effective manner. Possible industries can be packaging, food, medical and also many other applications such as

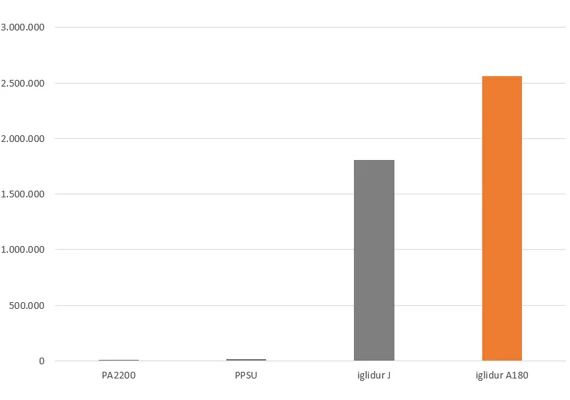

Service life in cycles: Apiro worm gear made of iglidur® A180 on aluminium h.c.

i=32, 20rpm at 3.5Nm

Continuous quality testing at our in-house test laboratory - also for customer applications We are also happy to test your application in order to better assess application scenarios.

Monday to Friday from 7 am - 8 pm.Saturdays from 8 am- 12 pm.

24h