Change Language :

Rotating energy supply for all media in a complete system

Applications with circular movement require a special energy supply: We call it rotating energy supply. Thanks to our decades of experience, we have mastered this challenge for our customers worldwide. We offer highly customised solutions developed for your application. For simple applications, we also offer derived standards in our online shop. These can either be configured or ordered as a predefined complete set.

Standards can be adapted flexibly and efficiently

The new standard for circular movements

Special solutions for special applications

Highlights of the rotating energy supply

Energy supply made easy

For several years now, igus® has been developing customised systems for circular movements with energy chains, known as rotating energy supply. This is used, for example, in machine tool construction, robotics and bucket wheel excavators to supply rotating assemblies with energy, data and fluids.

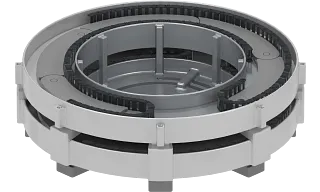

The igus® standard rotary modules consist of two circular guide elements. One part of the guide trough is attached to the static part of the system and the other part to the rotating part of the system. The fixed end of the e-chain® can be freely selected, as the rotary modules can be rotated both in the inner and outer part. Series E4.1 e-chain® and, for "simple" applications, series E2.1 and E2/000 energy chains are usually used for the rotary modules.

The standard for circular movements

- rotation angle up to 540° (in one plane)

- rotation angles of 900° and more are possible with the igus® multi-rotation module

- Maximum rotation angle in minimum installation space

- Rotation speed of up to 360°/s

- Lighter and more compact than static guide troughs

- Minimum displacement force and maximum service life

- Module design with standardised mounting variants

- Integrated strain relief and cable routing directly in the guide trough

- Determine rotating energy supply quickly and reliably via CAD configurator

What does "reverse bend radius" mean?

"Reverse Bend Radius" means that the e-chain® can bend in two directions. Versions with "Reverse Bend Radius" can be produced for many igus® e-chain®. The "Reverse Bend Radius" does not have to be identical to the normal "BR" (bend radius) of an energy chain. In this way, a wide variety of circular movements can be solved. Rotation angles of up to 900° have been realised to date.

**Tip: Solve your current design quickly, simply and easily by simply enquiring about your specific application with your igus® specialist for rotating energy supply. We will provide you with the correct design, the simplified 3D model and a concrete offer with prices and delivery times.

What does "MRM" mean?

"MRM" stands for multi-rotation module and is effectively a multi-level RBR system. With a simple igus® rotation module (such as a standard RBR energy chain), a rotation angle of up to 540° can be achieved, depending on the energy chain size. Each additional module extends the angle of rotation by up to 360°. A simple stop-dog system carries the system's upper layer according to a defined angle of rotation. This technology means that only one control system is required for both layers.

Your options with igus® guide trough

Depending on the application, the e-chain® slides on surfaces made of plastic, stainless steel or galvanised steel and is guided in a defined circular movement by special guide plates.

Suitable products and tools

Consulting

I look forward to answering your questions

igus® GmbH+49 2203 9649-0Write e-mail

Shipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Friday: 8 am – 5 pm