Change Language :

Stainless steel linear modules SHT drylin®

Robust, corrosion-free and resistant to chemicals

The installation sizes of the SHT-ES stainless steel linear modules

Technical options for the SHT series

The following options can be configured directly online for the SHT product range.

Configured, designed and ordered in just a few minutes

More stainless steel linear axes

drylin® technical accessories - control elements

Not all stainless steels are the same

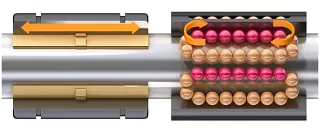

The principle: "sliding instead of rolling"

The advantages of plain bearing foils compared to recirculating ball bearing systems

The plain bearing foils made of high-performance polymers used by igus® are lubrication-free, maintenance-free and therefore the ideal partner for stainless steel linear modules. The combination of plain bearing system and stainless steel linear axis is used in certain applications due to the advantages of the linear drive system.

Customer application examples

Consulting

I look forward to answering your questions

Michael Hornung+49 2203 9649 0Write e-mail

Shipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Friday: 8 am – 5 pm