After selection of your ZIP code, we designate the relevant staff to attend to you at once.

After selection of your ZIP code, we designate the relevant staff to attend to you at once.

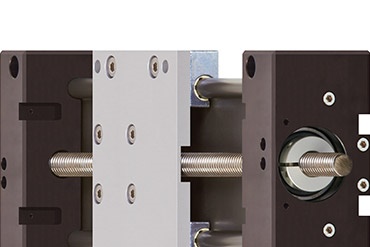

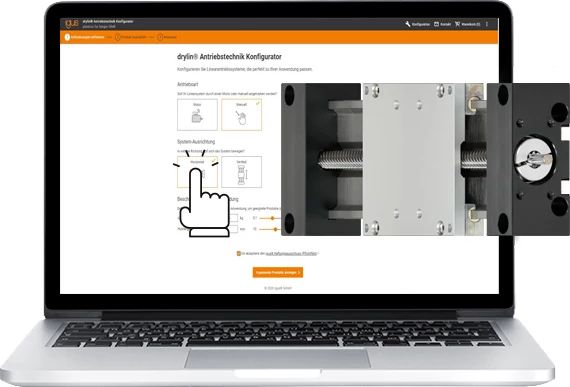

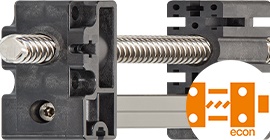

Across models, the linear modules can be equipped with trapezoidal or high helix lead screws. Linear axes with toothed belt drive are designed for long travels and very high speeds in applications with high repeatability and short throughput times.

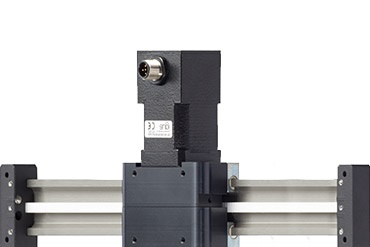

The linear units for high speed and long travels with direct power transmission via racks offer the additional benefit of allowing multiple carriages to move independently of each other and clearance-free on a single system.

Lubrication-free due to polymer bearings and polymer nuts

23 shaft materials

38 trapezoidal thread pitches, 4 high helix thread pitches

Body material made of stainless steel, aluminium, zinc or polymer

5Lead screw machined to drawing or plain drive shaft

6Accessories available

End supports with ball bearing

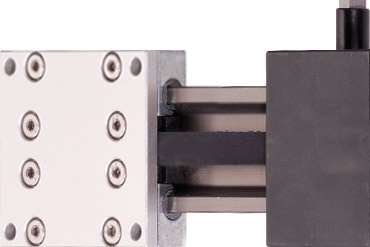

2Lubrication-free linear guide with polymer plain bearings

3Various carriage lengths

Polyurethane (PU) or neoprene toothed belt

5Hard-anodised aluminium

Direct force transfer via rack

2Torsional rigidity through aluminium hollow shaft drylin AWMR

Lubrication-free and maintenance-free due to drylin R linear liners

4Dynamic mass (0.9 kg) enables fast operation

Monday to Friday from 7 am - 8 pm.Saturdays from 8 am- 12 pm.

24h