After selection of your ZIP code, we designate the relevant staff to attend to you at once.

After selection of your ZIP code, we designate the relevant staff to attend to you at once.

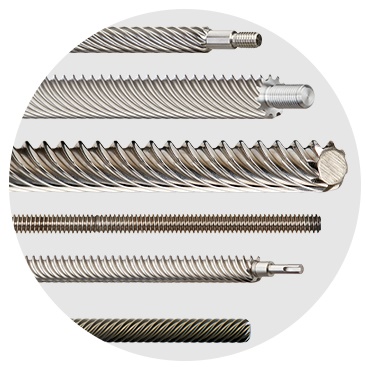

The number of passengers on public transport has been increasing steadily for 20 years. This is good news for the industry, but it also places an increasing burden on the rail network, trains and their individual components, such as sliding doors. Long-lasting lead screw drives which meet the high requirements, such as minimising wear and increasing service life are in demand. drylin lead screw technology is convincing and has already proven itself in many railway applications.

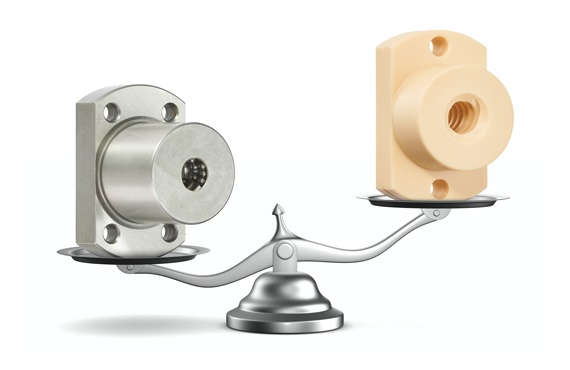

How would it be if maintenance efforts and costs were reduced and regular lubrication became unnecessary? And what if efficiency and effectiveness increase significantly? drylin lead screw technology offers the perfect alternative to conventional metal lead screw nuts for railway technology. It is completely lubrication-free and maintenance-free and therefore ideally suited for 24/7 operation.

Benefits:

► Dirt-resistant

Monday to Friday from 7 am - 8 pm.Saturdays from 8 am- 12 pm.

24h