Change Language :

Front loader test rig

Swivelling wear, single travel mode

Swivelling angle: 55°; load: 22 Mpa

Test result

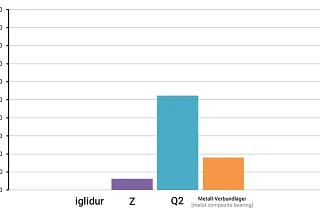

Not all iglidur® materials are suitable for use on an electrogalvanised surface. The reason for galvanising is to give the treated material protection against corrosion. Therefore, not only the wear rate must be considered in a bearing system, but also the condition of the counterpart; in this case the galvanised shaft. In combination with iglidur® Q2, on the one hand there is quite high wear, on the other hand it can be observed that the galvanised surface of the shaft is "worn in". Corrosion protection is no longer provided in this contact area. In combination with iglidur® Z, on the other hand, the wear rate is very low and the shaft surface is not affected in any way. The metal-rolled bearing exhibits relatively low wear. However, the surface is no longer intact in this system either. The risk of corrosion and the resulting consequences is high.

Products used

Consulting

I look forward to answering your questions

André Schönhaar+49 2203 9649 8316Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Chat-Service

Monday to Thursday from 8 am - 6 pm.

WhatsApp-Service:

Monday to Thursday from 8 am - 4 pm.