- For medium duty applications

- PUR outer jacket

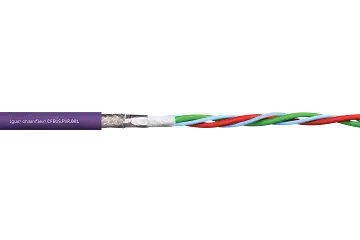

- Overall shield

- Coolant-resistant

- Notch-resistant

- Oil-resistant (according to DIN EN 50363-10-2)

- Flame retardant

- PVC-free

- Hydrolysis and microbe-resistant

- UV-resistant

- Halogen-free

- CMX (Communications Cable)

- chainflex® class: 4.3.3.1

chainflex® bus cable CFBUS.PUR

Typical application areas

- For medium duty applications

- Almost unlimited resistance to oil

- Indoor and outdoor applications without direct sunlight

- Unsupported travel distances and up to 20m for gliding applications

- Bus connection cable for processing/machine tools, low-temperature applications

Guaranteed service life for this series according to guarantee conditions

Further information: chainflex® guarantee

| Double strokes* | 5 million | 7.5 million | 10 million |

|---|---|---|---|

| Temperature, | R min. | R min. | R min. |

| from/to [°C] | [Factor x d] | [Factor x d] | [Factor x d] |

| -20 / -10 | 15 | 16 | 17 |

| -10 / +60 | 12.5 | 13.5 | 14.5 |

| +60 / +70 | 15 | 16 | 17 |

* Higher number of double strokes possible - use the service life calculation function on this page.

Technical note on bus cables

chainflex® bus cables have been specially developed and tested for continuously moving use in e-chains® applications. Depending on the outer jacket material and the design principle, the bus cables are designed for different mechanical requirements and media resistance. The cables have been electrically designed in such a way that, on the one hand, the electrical requirements of the respective bus specification are reliably met and, on the other, that great value is placed on a high degree of EMC reliability. It is also ensured that the electrical values remain stable over the long term in spite of permanent movement. However, the overall quality of transmission in a complete bus communication system is not solely dependent on the cable used. Rather, it requires precise co-ordination of all components (electronic components,

connection technology and cable) as well as observing the maximum transmission levels depending on the respective systems in relation to the required data transmission rates. A cable is therefore not solely responsible for the secure transmission of signals.

igus® advises you when you are designing your bus system to take all these factors into account and, with extensive tests, helps you to ensure the process reliability of your system from the very beginning.