Change Language :

Examples of successful applications in the machine tool industry

Overview of applications with igus products in machine tools

CNC machines: Overview of applications

CNC (Computerised Numerical Control) machines have become indispensable in the industrial processing of materials. The use of computer technology in industrial processing not only increases precision and therefore manufacturing quality when processing workpieces, it also significantly increases productivity. CNC-supported machines are used today in a wide variety of applications. Our energy chains, linear guides and plain bearing systems are used in this selection of CNC milling, drilling, grinding, turning, cutting, polishing and bending machines.

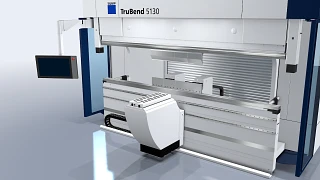

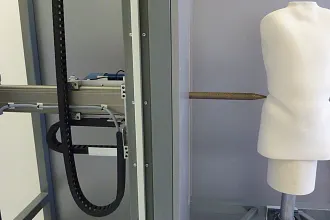

Energy tubes in bending machine

Whether bending simple or complex parts, with TruBend machines from TRUMPF, a wide variety of workpieces can be bent quickly and reliably with maximum precision. For large and heavy parts, a bending aid supports the machining process. TRUMPF relies on our R4.1L series energy tubes to ensure the safe energy supply of this support.

Welding system

Hanging, upright or linear: Our closed energy chains have been proving their worth in Cloos welding systems for years.

To the application example

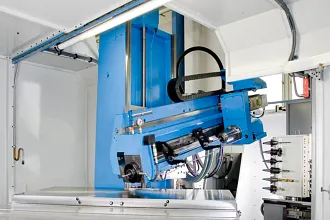

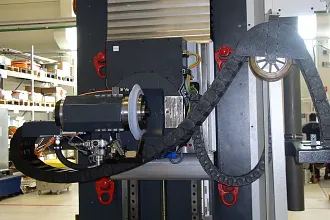

Combination machine for milling and drilling

For the energy supply to the main spindle of this milling and drilling machine, the manufacturer relies on particularly tight RX energy tubes.

To the application example

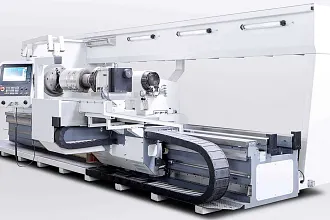

Horizontal lathe

A guidelok e-chain is used on this lathe for a travel of up to 20 metres. It is perfect for long, unsupported travels in the swarf area.

To the application example

Machining centre

ROMI, market leader in the Brazilian machine and plant industry, has been supplied by us for 15 years. Our e-chains and chainflex cables are used in a new machining centre.

To the application example

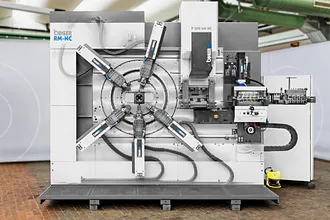

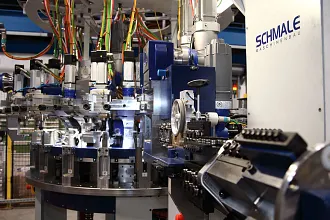

Multi-spindle lathe

A readychain system with a total of eight energy chains guarantees safe energy supply to all six spindles of this lathe from Gildemeister Italiana S.p.A.

To the application example

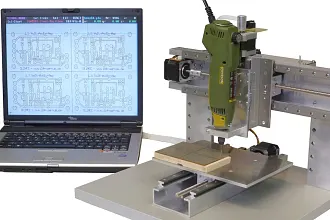

Compact milling machine

These compact CAD/CAM milling machines produce prototypes quickly, precisely and with high quality. 15 drylin miniature guides and dryspin lead screw nuts were installed here.

To the application example

Milling machine for bicyles

15 e-chains are used in a milling machine in all travel axes, the lifting cabin and in the tool changer. They guarantee long travels of up to 50 metres.

To the application exampleAdverse ambient conditions (use of chemicals, high levels of dirt, flying swarf)

Aggressive ambient conditions usually occur when metal is being machined. Metallic grit, but also clogging oils for lubrication of machine parts, affect elements such as the cable guide or linear guide systems. Closed energy chains or energy tubes are often used to protect the internal cables in order to operate machines with as few interruptions and failures as possible.

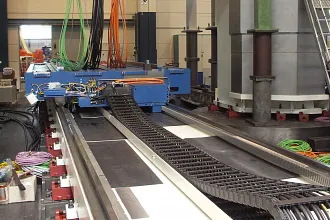

Energy tubes in milling machines for heavy-duty machining

Large machining centres in gantry design are the speciality of machine tool manufacturer Kao Ming from Taiwan. The long travels of up to 13 metres place special demands on the supply of energy and media in these systems. With the guidelok, Kao Ming has opted for a system that is reliable, robust and unsupported.

Heavy-duty lathe

Chip and dirt require closed energy chain with a long service life in this system from lathe manufacturer FAT HACO.

To the application example

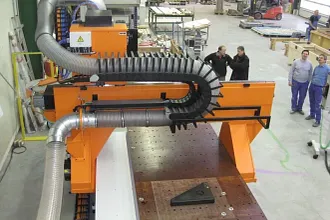

Cutting system

Particularly dirty and abrasive conditions characterise the environment in knife cutting systems. e-chains in combination with an autoglide system are used here.

To the application example

Milling machine

This CNC machine mainly mills polystyrene, which clogs all surfaces and gaps. The customer therefore uses drylin linear units today.

To the application example

Polishing milling machine

This polishing milling machine is used in the field of "prosthetics". Fine dust settles on the linear guides during milling. drylin linear units now provide a remedy.

To the application example

Milling and turning machines

The spaces between threaded rods quickly become clogged with dirt. The special dryspin lead screw nuts maintain the performance of the machines thanks to their cleaning function.

To the application example

Flame cutting machine

Movable in all directions, multi-axis energy chain ensure endlessly pivoting axes. They prove themselves against heat, flying sparks and extreme dirt accumulation.

To the application example

Machining centre

All components in this CNC machining centre had to be resistant to temperature and chemical resistance. Special e-chains are used here, from which the swarf simply bounce off.

To the application example

Gantry milling machine

A robust high-temperature energy tube is used in this milling machine. Even swarf up to a temperature of 850°C bounce off without a trace.

To the application exampleTight installation space and minimal bend radii

In the further development of machine tools, designers are looking for ways to reconcile ever more powerful systems with the endeavour to find space-saving solutions. This not only enables smaller dimensions for the entire system, but also offers considerable potential savings in terms of energy costs during operation. In this context, energy chain, for example, must allow very small bend radii at high travel speeds and accelerations.

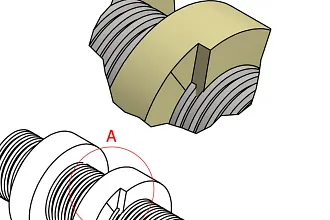

chainflex cables supply KESSLER lead screws with power and signals

The "System Technology" division of the renowned motorised spindle manufacturer FRANZ KESSLER develops and produces pivoting spindle heads and rotary pivoting tables, which enable a very precise processing of metal and increasingly also composite workpieces. For the power and signal supply, KESSLER uses chainflex cables that fulfil very high requirements in terms of service life and reliability.

Servo punching and bending machines

Our energy chains and chainflex cables, which travel in a very confined space in the machine, supply energy to the fastest servo punching and bending machines in the world.

To the application example

High-performance turning centre

In the vertical EMAG turning centres of the VMC series, chainflex single-core cables are used to supply power to the spindle. The challenges: Limited space, high chip volume and oil.

To the application example

Automatic drilling machine

Up to fifty servo axes in a confined space, high dynamics, high demands on service life and small bend radius. These are the requirements of this automatic drilling machine for our energy chain and chainflex cable.

To the application example

Gear grinding machine

Achieving a vertical stroke of over one metre and a pivot range of 270° in a limited installation space was possible with this application in the grinding head of a gear grinding machine.

To the application example

Multi-spindle machining centre

In this application, a two-spindle horizontal machining centre was equipped with very quiet and low-vibration energy supply systems.

To the application example

Press automation system

This press automation system requires extremely space-saving energy supply at high speed.

To the application example

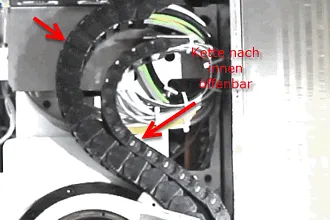

"Heavy duty" gantry machine

A space problem was solved here with a simple trick: only 20cm installation height was available, too low for a conventional solution with an e-chain.

Machine tool for metalworking

Two e-chains run side by side in a machine tool from machine manufacturer Yamazaki Mazak Corp. and enable energy to be supplied in a very small installation space.

To the application example

Stretch-bending machine

Due to the limited installation space, forced guidance of the energy tubes was necessary in this CNC inclined-bed lathe. Energy tubes ensure 3-dimensional media guidance here.

To the application example

Milling centre

The application is the pivot head of a milling centre. Energy chains guide a large number of media to a milling head in a very small installation space.

To the application exampleLong service life under continuous operation

When developing machine tools, a particular focus is placed on the high availability of the solution. The aim is to reduce downtimes and thus enable the customer to operate the machine as economically as possible. The high-quality systems often have to be able to cope with three-shift operations seven days a week without any problems. In the following application examples, the customer focussed on energy chains, linear guides or plain bearings that work reliably under the high and continuous stress from movement.

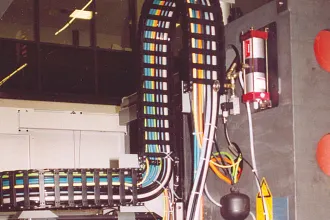

Energy chains and abrasion monitoring in engine plant

In hardly any other industry is reliability as important as in the automotive industry. Because production downtimes are expensive, it is important for vehicle manufacturers and suppliers to be able to rely on dependable components. An Austrian engine manufacturer therefore relies on 'smart plastics' from igus. Sensors detect wear during operation and raise the alarm in good time as soon as a repair or replacement is required.

Recycled energy chain in press brake

Bystronic uses a 100% recycled energy chain as standard in the ByBend Star 120. The heavy-duty cable guide enables a CO₂ reduction of up to 28%.

To the application example

Thread drive in edge milling machine

Esmatec GmbH uses maintenance-free lead screws and flanged lead screw nuts in its first fully automatic edge milling machine "e-master", which reduce the assembly costs of the machine and increase its service life.

To the application example

Turning and grinding machines

Top condition even after nine years - pre-fitted energy supply systems are used in these precision machines under aggressive environmental conditions.

To the application example

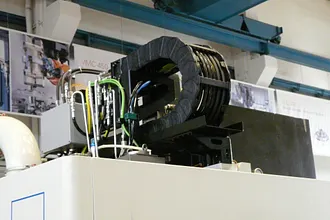

Friction stir welding machine

24 hours a day, seven days a week, a closed R4 type energy tube is in operation in a friction stir welding machine from Grenzebach Maschinenbau GmbH.

To the application example

Milling machine

The DMF 200|8 milling machine from DMG Mori achieves milling speeds of up to 20,000rpm. Energy chains of the E4Q series reduce vibrations in the machine.

To the application example

CNC multi-spindle automatic lathe

Every spindle in this automatic lathe from Schütte has to be supplied with energy, signals and coolant. And that with more than 4.5 million cycles per year.

To the application example

Large machining centre

These machine tools for machining large components are often in use for 20-30 years with a required availability of at least 95%. Energy chains and chainflex cables are used here.

To the application example

Cutting machine

An e-chain of type E6 is used in this cutting machine. This must guarantee a planned machine service life of seven to 10 years, even under high loads in continuous operation.

To the application example

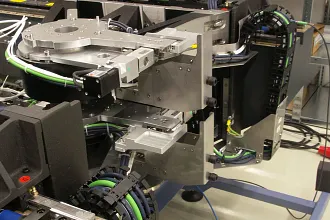

Positioning systems in electronics production

The readychain systems are used in this positioning unit to safely guide the drive, measuring system and compressed air cable - 24 hours a day, 7 days a week.

To the application example

Concrete pipe cutter

This milling machine produces aluminium chips, wood chips and fine dust from composite materials. Energy chains and bearing technology are used here, which must always work reliably.

To the application example

Machines for micro-assembly

These micro-assembly machines manage several million work cycles per year. Energy chains and chainflex cables hold their own as reliable system components under this continuous load.

To the application exampleQuick and easy assembly

Nowadays, modern machine tools can take several months from assembly to commissioning. However, in order to ensure ongoing operation at an earlier stage, highly complex systems should ideally be ready for operation after just a few weeks. Sophisticated modular products, expert advice and the reduction of the supplier base were able to contribute to this goal in the following applications.

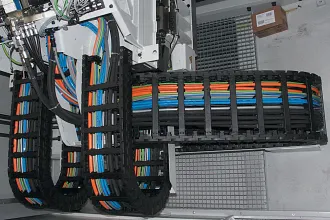

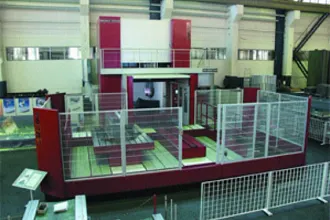

readychains reduce process costs in CNC systems

The machine tool manufacturer Hartford from Taiwan relies on completely harnessed energy chain systems in its gantry machining centres. This saves many work steps, reducing the assembly time required from several weeks to just half a day. At the same time, customers can always rely on readychains to provide them with a reliable solution from a single source.

Machine tool series

In order to save space, weight and time when completing its machine tools, DVS Universal Grinding GmbH relies on pre-fitted energy chains.

Go to user report

Grinding machine

An extremely smooth-running chain enables this CNC machine to work with precision. A simple design minimises installation and maintenance costs.

To the application example

Gantry milling machine

With pre-fitted readychain energy supply, the company receives everything from a single source and directly from the manufacturer. This saves assembly time and costs.

To the application example

Machining centre

The E4/4 light energy chain offers compact external dimensions and a very robust design. The readychain system saved the customer assembly time and costs and made installation considerably easier.

To the application example

Gantry machining centre

The energy supply system for this machining centre has been designed to minimise the number of interfaces. A pre-fitted complete solution ensures a cost and time-saving assembly.

To the application example

Grinding machine

The linear guide and plastic bearing used in this grinding machine are characterised by their freedom from maintenance and lubricants and guarantee a very long machine service life.

To the application exampleOther user reports

Machine tools in general

By replacing metallic bearings with iglidur plastic bearing, Deckel Maho Gildemeister was able to achieve cost savings of over 50 per cent on its machine tools.

To the application example

Waterjet cutting system

This XXL waterjet cutting system has impressive dimensions with a travel of 32x5 metres. Energy supply systems support the precise movement of the two 3D cutting heads.

To the application example

Toothed belt unit with guide system

Parker EME uses drylin guide systems in its linear actuator "LCB". They are extremely robust, have optimum wear and friction properties and require no lubrication.

To the application example

Wire bending machine

The SPEEDMAX bending machine series combines an extremely high cycle performance with minimal strokes. Due to the exceptionally high load, the customer now relies on robust iglidur plain bearings.

To the application example

Machining centre

Today, lightweight, robust and lubrication-free polymer bearings are installed in a wide variety of places in machine tools and machining centres. They always work reliably despite the many movement cycles of the machines.

To the application example

Laser cutting machine

This laser cutting machine is characterised by high travel speeds and accelerations. Here, energy chains operate with both dynamism and robustness.

To the application example

Woodworking machine

Trima Triebeser Maschinenbau GmbH has installed an e-chain with extender crossbars for the 300mm thick suction hose for a woodworking machine. The aim was to realise a cable-friendly and robust guide over a long travel.

To the application exampleConsulting

I look forward to answering your questions

Markus Kogelmann+49 2203 9649 7704Write e-mail

Shipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Friday: 8 am – 5 pm