Change Language :

iglidur® M250 - material data

Temperature

Short-term application temperatures of up to +170°C are permissible. However, iglidur M250 plain bearings may only be exposed to this temperature without any additional load. The upper long-term application temperature is +80°C. This is also the wear limit, i.e. the temperature at which wear increases disproportionately. An additional safety device is required for temperatures above +60°C.

| min. application temperature | Upper application temperature, long-term | Upper application temperature, short-term | In addition secure axially from |

|---|---|---|---|

| -40°C | +80°C | +170°C | +60°C |

Permissible surface speeds

As standard, iglidur M250 is manufactured as a thick-walled bearing. iglidur M250 is best suited for low to medium surface speeds. The maximum permissible surface speed in dry operation is 0.8m/s (rotating) or 2.5m/s (linear). In practice, these limit values cannot always be achieved due to the interaction of different influences.

Sliding speeds of various iglidur materials

| m/s | Rotating | Oscillating | linear |

|---|---|---|---|

| permanent | 0.8 | 0.6 | 2.5 |

| Short-term | 2 | 1.4 | 5 |

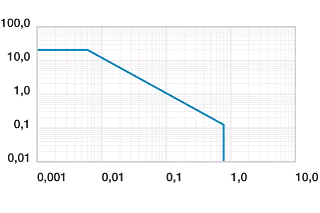

Permissible pv values

Mechanical properties

When temperatures increase, the compressive strength of iglidur M250 plain bearings decreases. The maximum recommended surface pressure is a mechanical material parameter. No conclusions regarding the tribological properties can be drawn from this. iglidur M250 plain bearings can withstand a maximum recommended surface pressure of 20MPa. Compared with other iglidur materials iglidur M250 plain bearings are highly elastic. By this elasticity they can yield very well, but retain their original shape again. A plastic deformation is minimal up to the maximum recommended surface pressure.

Friction and wear

The coefficient of friction μ of a plain bearing is influenced by surface speed and load, among other things.

Coefficients of friction for iglidur M250 against steel (Ra = 1μm, 50HRC):

| iglidur M250 | dry | Greases | Oil | Water |

|---|---|---|---|---|

| Coefficient of friction µ | 0.18-0.40 | 0.09 | 0.04 | 0.04 |

Shaft materials

Friction and wear are also highly dependent on the mating partner. Looking at the coefficient of friction, the most favourable surface finish of the shaft for iglidur M250 bearing is Ra = 0.6mm. Diagrams 06 and 07 show an extension of the results of tests with different shaft materials that were carried out with iglidur M250 plain bearings. Up to a load of 2MPa, the shaft material plays a comparatively minor role in rotation. A suitable shaft material should therefore be used for higher loads. These are hardened shafts, such as Cf53 or hard chrome-plated shafts. Diagram 07 shows that iglidur M250 is much better suited for rotary movements than for pivoting movements. However, it must be mentioned that in practice the vibrations acting on the bearing are often particularly high during pivoting movements. This is where iglidur M250 can utilise its special dampening specifications. Such vibrations are excluded in our test, so the comparison between rotation and pivoting operation is initially surprising.

Further information on shaft materials

Installation tolerances

iglidur M250 plain bearings require relatively large bearing clearances for optimum operation. This ensures that the bearing bushes work reliably even with temperature expansion and total moisture absorption. The disadvantages of the bearing clearance are compensated for by the vibration-dampening specifications. The bearings are designed for press-fit into an H7 tolerance housing. After installation in a housing with nominal dimensions, the inner diameter of the bearing adjusts itself with D11 tolerance. The shaft should have at least h9 tolerance.

| Diameter d1 [mm] | Shaft h9 [mm] | iglidur M250 plain bearing D11 [mm] | Housing H7 [mm] |

|---|---|---|---|

| up to 3 | 0 - 0.025 | +0.020 +0.080 | 0 +0.010 |

| > 3 up to 6 | 0 - 0.030 | +0.030 +0.105 | 0 +0.012 |

| > 6 up to 10 | 0 - 0.036 | +0.040 +0.130 | 0 +0.015 |

| > 10 up to 18 | 0 - 0.043 | +0.050 +0.160 | 0 +0.018 |

| > 18 up to 30 | 0 - 0.052 | +0.065 +0.195 | 0 +0.021 |

| > 30 up to 50 | 0 - 0.062 | +0.080 +0.240 | 0 +0.025 |

| >50 to 80 | 0 - 0.074 | +0.100 +0.290 | 0 +0.030 |

| >80 to 120 | 0 - 0.087 | +0.120 +0.340 | 0 +0.035 |

| > 120 up to 180 | 0 - 0.100 | +0.145 +0.395 | 0 +0.040 |

Moisture absorption

The moisture absorption of iglidur M250 plain bearings in a normal climate is around 1.4% weight. The saturation limit in water is 7.6% weight. This must be taken into account under appropriate operating conditions.

Chemical resistance

iglidur M250 plain bearings have good resistance to chemicals. They are resistant to most lubricants. Most weak organic and inorganic acids do not attack iglidur M250.

+ resistant 0 conditionally resistant - non-resistant

All data at room temperature [+20 °C]

| Medium | Resistance |

|---|---|

| Alcohols | + up to 0 |

| Hydrocarbons | + |

| Greases, oils without additives | + |

| Fuels | + |

| Diluted acids | 0 to - |

| Strong acids | - |

| Diluted alkalines | + |

| Strong alkalines | 0 |

Electrical properties

iglidur M250 plain bearings are electrically insulating

| Resistance | Value |

|---|---|

| Specific transitional resistance | > 1013 Ωcm |

| Surface resistance | > 1011 Ω |

Radioactive radiation

Plain bearings made of iglidur M250 can be used to a limited extent under radioactive radiation. They are resistant up to a radiation intensity of 1 · 104Gy.

UV resistance

iglidur M250 plain bearings are permanently resistant to UV radiation.

Vacuum

In a vacuum, iglidur M250 plain bearings outgas. The relatively high moisture absorption of the bearing therefore limits its use in a vacuum.

Buy iglidur M250 products in the online shop

- Large selection of moulds and materials

- Available within 24 hours

- No minimum order quantity

- No minimum order quantity

Typical application areas

Consulting

I look forward to answering your questions

Shipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Friday: 8 am – 5 pm