Change Language :

Hybrid energy chain YE - strong, shake-proof and compact

The hybrid energy chain YE is the best mix of lightweight plastic and strong steel that can easily handle high unsupported travels. It was developed to meet the requirements of construction machinery and lifting equipment. The requirement was to offer the maximum possible unsupported length with compact dimensions and the lowest possible weight. However, pure steel energy chains have the disadvantages of high assembly costs and weight. The YE system combines the higher strength of steel elements with the low weight and flexibility of plastic components. In addition, no screws, rivets or bolts are used, which can loosen under vibration.

- Almost 50% less weight than comparable steel chains

- YE.42: 91% more unsupported length compared to the E4.42 series

- YE.56: 61% more unsupported length compared to the E4.56 series

- YEHD.112: 68% more unsupported length compared to the E4.112 series

e-chain® with crossbars every 2nd link, openable from both sides

Series YE.42

Inner height hi: 42mm

Outer height ha: 76mm

Inner width Bi: 100 - 400mm

Outer width Ba: 118 - 418mm

Bend radii R: 100 - 150mm

Pitch: 67mm

YE.56 series

Inner height hi: 56mm

Outer height ha: 90mm

Inner width Bi: 100 - 600mm

Outer width Ba: 124 - 624mm

Bend radii R: 100 - 500mm

Pitch: 91mm

iSet YE | Travels: 6 - 18m

Save time and money with our complete energy chain system. No need to spend a lot of time searching for the right accessories. Suitable for construction machinery, cherry pickers, telescopic loaders, construction machinery.

Buy nowe-chain® with crossbars every link, openable from both sides

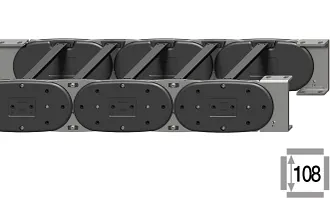

YEHD.108 series

Inner height hi: 108mm

Outer height ha: 146mm

Inner width Bi: 387 - 550mm

Outer width Ba: 435 - 598mm

Bend radii R: 250 - 600mm

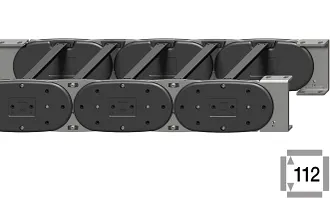

YEHD.112 series

Inner height hi: 112mm

Outer height ha: 146mm

Inner width Bi: 100 - 600mm

Outer width Ba: 148 - 648mm

Bend radii R: 250 - 600mm

e-tube, openable from both sides, pivoting lid - protection against chips and dirt

Realised in practice

Order a free sample

Order a free sample of YE and see the quality of the product for yourself.

Tech up

- Almost 50% less weight 1

- 50% longer unsupported length 2

- High tensile strength

- No screws, rivets or bolts that

can become loose under vibration - Robust: steel mounting brackets with attachment options from any side

- Smooth operation due to plastic pin connection

- Wide range of interior separation elements

1As a pure steel chain of comparable size

2As a comparable plastic e-chain

Cost down

- Easy installation - plastic outer links

with flange for easy assembly of the

e-chain links - Available as a ready-to-install readychain system with cables,

hoses and hydraulic components - Intelligent breakage detection - available with i.Sense EC.B to avoid unplanned downtimes.

Proof

- First customer applications with high additional loads are already running

- Tested in the igus laboratory: comparison of YE(HD) vs. E4.1 unsupported length at 5kg/m fill weight

Sustainability

- Easy installation - plastic outer links

with flange for easy assembly of the

e-chain links - Available as a ready-to-install readychain system with cables,

hoses and hydraulic components - Intelligent breakage detection - available with i.Sense EC.B to avoid unplanned downtimes.

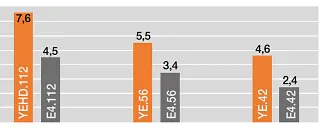

Test run: unsupported length with straight upper run with 5kg/m fill weight

Unsupported length FLG at 5kg/m fill weight

igus compared the YE(HD) and E4.1 in its test laboratory, which is the largest in the industry. Both systems were evaluated in terms of their unsupported length unsupported with straight upper run at 5kg/m additional load.

Result:

With an additional load of 5kg/m, the YEHD.112 series can travel unsupported up to 7.1m and the E4.112 series reaches 4.5m. The YE.56 series can travel up to 5.5m unsupported, the E4.56 series reaches 3.4m. The YE.42 series can travel unsupported up to 4.6m, the E4.42 series reaches 2.4m.

Free white paper: Energy supply for machines with inclined axes

Whether on construction sites, fire brigades or Hollywood films: Aerial work platforms with inclined axes and telescopic extensions are used all over the world. Their designers need energy supply systems that are light, robust, resistant and easy to maintain. Manufacturers have therefore spent decades investing in research and development. In this white paper, you can read about the advantages of the YE hybrid chain for aerial work platforms as well as other machines and applications.

Why plastic-steel hybrid energy chain

Standard steel energy chains in cherry pickers vs. igus YE hybrid energy chains

Everything you need to know about telescopic work platforms and cherry pickers

See the quality of our products for yourself. The sample box contains a selection of igus solutions for use in telescopic extensions and inclined axes.

Consulting

I look forward to answering your questions

Dieter Reitz+49 2203 9649 7070Write e-mail

Shipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Friday: 8 am – 5 pm