Change Language :

autoglide 5 – Energy and data transmission installed in one hour

88 % assembly time saved with new cost-effective energy chain for material handling and crane systems

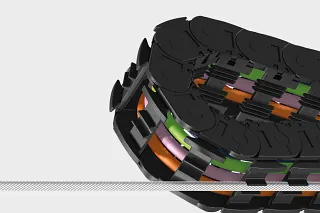

The igus® system autoglide 5 transmits energy, data, fluids and air in one system safely and almost maintenance-free at a cost-effective price, including e-chain® 2400.07AG.075.0, steel cable guide, bus cable assembly and 5 individual wires of 6 mm² each.

Technical data:

| Travel | Speed | Noise during operation |

|---|---|---|

| 80m | 4m/s | 63dB(A) at 2m/s |

Tech up

Cost down

Proof

Sustainability

Product range:

2-part energy chain

| Part No. | Inner height | Inner width | Bend radius*** | |

|---|---|---|---|---|

| 2400.05AG5 | 25mm | 57mm | 075/100/125/150mm | To the shop |

| 2600.07AG5 | 35mm | 75mm | 075/100/125/150mm | To the shop |

| 2600.10AG5 | 35mm | 100mm | 075/100/125/150mm | To the shop |

4-part energy chain

| Part No. | Inner height | Inner width | Bend radius*** |

|---|---|---|---|

| E4.32.10AG5* | 32mm | 100mm | 100/125/150/175/200mm |

| E4.32.112AG5* | 32mm | 112mm | 100/125/150/175/200mm |

| E4.32.12AG5* | 32mm | 125mm | 100/125/150/175/200mm |

| E4.32.15AG5* | 32mm | 150mm | 100/125/150/175/200mm |

| E4.32.17AG5* | 32mm | 167mm | 100/125/150/175/200mm |

| E4.32.20AG5* | 32mm | 200mm | 100/125/150/175/200mm |

| E4.32.262AG5* | 42mm | 262mm | 125 / 150 / 160 / 175 / 200mm |

| E4.42.10AG5* | 42mm | 100mm | 125 / 150 / 160 / 175 / 200mm |

| E4.42.112AG5* | 42mm | 112mm | 125 / 150 / 160 / 175 / 200mm |

| E4.42.12AG5* | 42mm | 125mm | 125 / 150 / 160 / 175 / 200mm |

| E4.42.15AG5* | 42mm | 150mm | 125 / 150 / 160 / 175 / 200mm |

| E4.42.17AG5* | 42mm | 167mm | 125 / 150 / 160 / 175 / 200mm |

| E4.42.20AG5* | 42mm | 200mm | 125 / 150 / 160 / 175 / 200mm |

| E4.42.262AG5* | 42mm | 262mm | 125 / 150 / 160 / 175 / 200mm |

*Available from spring 2021

**Available from stock

*** Larger bend radius upon request

Busbar system vs. energy chain: in this video, industry manager Christian Strauch explains which KO criteria apply when choosing the system and which system is ahead in terms of price, safety, freedom from maintenance, installation and range of functions.

white paper: energy chain with steel cable guide as an alternative to the busbar system?

For the power supply of indoor or outdoor cranes, electric hoists and storage and retrieval machines, many users have so far relied on busbar systems. The price is on a par with a busbar system, but with advantages in terms of installation, modularity and maintenance. autoglide 5 combines the best of both worlds. Read more in the white paper "energy chain with rope guide as an alternative to the busbar system?"

The user's problem:

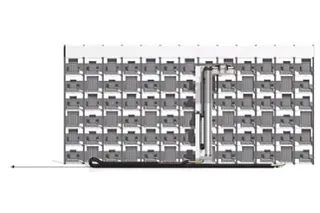

For power and data transmission in tight, compact spaces and for fast aisle movements, for example of storage and retrieval machines, many users have so far relied on busbar systems. These have a simple design and are therefore very cost-effective. Their major disadvantage is that they are expensive to maintain, can only be used for power transmission as standard and have to be cleaned regularly to prevent contact faults. In addition, they can usually only transmit energy.

Your advantages with autoglide 5:

- Can be easily set up in the aisle on a rope or profile

- Favourable price

- 88 % shorter installation time compared to aluminium channels

- Durable, maintenance-free and easy to clean

- Energy, data, air and liquids in ONE system

- 4 m/s speed

- 80 m travel

- Quiet running: 63 dB(A) at 2 m/s

- Hall floor remains clear, no guide trough required

- Available as a preassembled system with cable, hose and connector

How does it work?

The metal cable supplied is stretched across the floor of the lane. Alternatively, guidance via a plastic cable or profile is also possible.

The e-chain® can travel safely on the cable. The underside of the chain links has a guide element in the centre so that the energy chain can rest securely on the cable. Comb-like autoglideelements ensure wear-resistant and precise rolling of the upper strand of the chain.

Assembly instructions

Thanks to the illustrated installation guide, you can install the autoglide 5 quickly and professionally.

autoglide 5 for many industries and applications

The autoglide 5 system is not only interesting for storage and retrieval machines (SRMs), miniloads or other material handling applications. We work with you to develop concepts and prototypes that can be realised efficiently thanks to the modular design of autoglide 5, the large selection of igus® energy chain and cable and our experience. Which parameters are decisive for you? What speed, filling or travel is required in your application? Ask us and we will work with you to develop a solution for your application that will reduce costs and improve the technology.

Increase availability and avoid downtime

... with i.Sense from smart plastic Tech up

- Increase machine availability and maximise service life

- Better fault analysis thanks to real-time machine data acquisition

- Easy integration into Industry 4.0/smart factory concepts

Cost down

- Elimination of unplanned downtimes or machine failures

- Reduce maintenance costs through early warnings

- Realisation of condition-based maintenance

Frequently asked questions FAQ

The basis is the 2400 with a width of 77 mm and a bend radius of 75 mm. Other widths and radii are of course also possible.

As with all e-chain®, we are aiming for 10 million cycles or 10,000 km. The tests in our laboratory for a guaranteed statement are still ongoing.

Yes, because the special crossbars are simply unfolded. Should they ever wear out, they can be easily replaced.

We are currently testing the use of a plastic rope.

Application examples with autoglide

Consulting

I look forward to answering your questions

Dieter Reitz+49 2203 9649 7070Write e-mail

Shipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Friday: 8 am – 5 pm