Change Language :

Bag forming, filling and sealing machines

Flow-wrapping machines package products quickly and efficiently in pouch packaging - regardless of whether they are food, pharmaceutical or non-food products.

lubrication-free and low-maintenance motion plastic are the problem solvers in many areas of these machines, e.g. in the drive of the sealing bars, in the bag folder or in the format adjustment of the bag width.

Overview of flow-wrapping machines and products used

Vertical form, fill and seal machines (VFFS)

Tubular bag packaging machines quickly pack products, whether they are food, pharmaceutical or non-food products.

Vertically aligned, they can also be used in confined spaces. lubrication-free and low-maintenance bearing components such as profile rail systems or spindle lifting tables are used at various stations in these machines.

Products used and application examples

The stations of pouch packaging machines and the products we use are shown below as examples. Among other things, drylin® profile guides, spindle linear tables or iglidur® plastic plain bearings are used in the sealing bar, bag folder or in the format adjustment of the bag width.

Horizontal flow-wrapping machines (HFFS)

In horizontal flow-wrapping machines, a wide variety of products such as food, pharmaceutical products or non-food products are fed into pouch packaging and packaged. Our linear products such as profile rail systems or spindle lifting tables are used at various stations of these systems to ensure a smooth packaging process.

Products used and application examples

The stations of pouch packaging machines and the products we use are shown below as examples. Among other things, drylin® profile guides, spindle linear tables or iglidur® plastic plain bearings are used in the sealing bar, bag folder or in the format adjustment of the bag width.

Further application examples of our customers

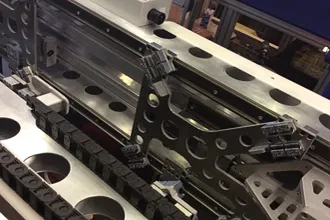

Flow wrapping machine

drylin® linear bearings ensure lubrication- and maintenance-free format adjustment in flow-wrapping machines.

Film sealer

drylin® SLW spindle linear modules enable lubrication- and maintenance-free format adjustment of the film sealing unit in this tubular bag machine.

Consulting

I look forward to answering your questions

Bastian Mehr+49 2203 9698 140Write e-mail

Shipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Friday: 8 am – 5 pm