Change Language :

Hygiene, precise and fast processing and safety in packaging technology

Use of igus® products in general packaging technology

Selected products for the packaging industry

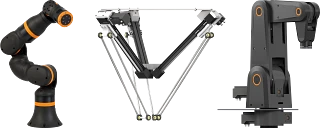

Cobots, delta pickers, gel arm robots and much more ...

Automation in the packaging industry

Automating processes with low complexity, fast integration into existing systems and a quick return on investment? That is the stated aim of our products from "Low Cost Automation".

white paper: Kolsterising and tribopolymers

Especially in an industry that depends on precise and fast processing with maximum purity and economy, the combination of colsterisation and high-performance plastics should become the standard ...

Format adjustment in the packaging industry - from manual to smart positioning

cable for the packaging industry

- drive cable suitable for 24 manufacturer standards in 7 qualities

- Solutions for e.g. Rockwell, Bosch-Rexroth, Schneider Electric, B&R, Siemens

- Over 1350 cables from stock, delivered within 24 hours

▶ Learn more now

Customer application examples

Tested for real use in the test laboratory

iglidur® bearings and drylin® linear technology are put through their paces in the industry's largest plastic test laboratory. Among other things, they are tested for media resistance (e.g. cleaning media), continuous load and low-noise operation. The results are fed into our tools for calculating service life and enable precise predictions to be made about durability.

Upon request, igus® also carries out customer tests in order to test the use of the products under very individual conditions.

More information

The large sample box

With the igus® corner, you always have the right motion plastic for your industry at your fingertips.

igus® blogs

Topics and trends from the packaging industry. Discover them now in our blog.

Consulting

I look forward to answering your questions

Bastian Mehr+49 2203 9698 140Write e-mail

Shipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Friday: 8 am – 5 pm