Change Language :

Tailored high-performance polymers for industrial vehicles

Industrial vehicle downtimes due to defects, repairs, or maintenance are annoying and costly and prevent the machines from being used. So robust, reliable components are needed to avoid downtime and reduce unnecessary costs. High loads at bearing points (up to 250MPa) or very small bending radii for cables: We have virtually maintenance-free solutions with long service life for industrial vehicles such as forklifts, industrial tractors, and automatic guided vehicles. In many applications, such elements as metallic bushings or recirculating ball bearing guides can be replaced with self-lubricating polymer plain bearings and linear guides! We would be happy to show you how to improve your technology while cutting costs.

Products for industrial vehicles

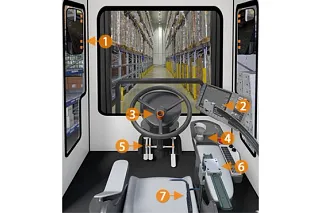

Products for industrial vehicle cabins

- Mirror adjustment: Low friction and wear values with iglidur J plain bearings

- Monitor adjustment: Flexible and easy positioning with drylin W guide carriages

- Steering column bearing: High resistance to dirt with iglidur G plain bearings

- Hydraulic valve connection: Compensation of misalignments with igubal double joint

- Pedal mechanism: Clearance-free pre-loaded bearings with iglidur JVSM

- Armrest adjustment: Easy dry operation with drylin W linear guides

- Seat bearing adjustment: Safe energy supply with E2 e-chain and chainflex cables

Tested in the test laboratory for use in the real world

Tested for continuous load, media resistance and quiet operation

In the industry's largest plastics test laboratory, iglidur plain bearings, drylin linear technology and igubal coupling joints are put through their paces. The focus is on testing assemblies and examining the tribological specifications of different material combinations. The results are incorporated into our service life calculation tools and allow exact durability predictions.

Upon request, igus performs customer tests to check product use under specific conditions.

More information

Consulting

I look forward to answering your questions

Marc Waterkamp+49 2203 9649-346Write e-mail

Shipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Friday: 8 am – 5 pm