Change Language :

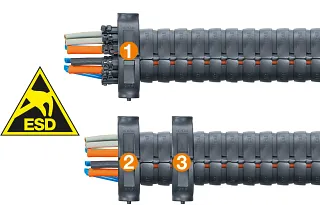

Electrostatically conductive 3D energy chain

energy chains made of conductive ESD material are used to prevent static charges in the manufacturing processes of electronic components or assemblies. As early as 1992, igus® GmbH, together with the PTB (Physikalisch-Technische-Bundesanstalt) in Braunschweig, carried out measurements of the electrical surface leakage resistance for igus® energy chain with the special material igumid® GC, supplemented by further certifications in 1998 and 1999 according to DIN 53482 as well as the guideline on static electricity ZH1/200 of the Hauptverband der gewerblichen Berufsgenossenschaften.

Closed type especially for robots and three-dimensional applications

from stock available sizes of ESD chains

Other sizes of triflex® R e-chain® in ESD material available upon request

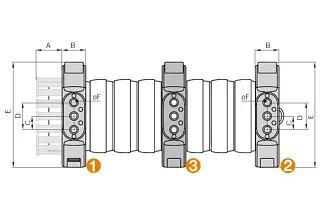

Mounting bracket in ESD material

Available with strain relief from stock

- Quick and easy fixing of the energy chain

- Shortest downtimes when replacing a filled triflex® R

- Mounting bracket with strain relief teeth (1)

- Mounting bracket without strain relief teeth (2)

- mounting bracket as intermediate bracket (3)

- Quick assembly with captive snap-lock mechanism

- Adaptation holes for common robot types

- End or intermediate mounting possible

With strain relief in 3 sizes in ESD material available from stock

Possible applications of the mounting bracket

1 = mounting bracket with strain relief TR.XX.01

2 = mounting bracket without strain relief TR.XX.02

3 = mounting bracket as intermediate bracket TR.XX.02

Strain relief is possible at the fixed end and/or at the moving end!

Standard: plain hole in ø F

Option: with threaded bushing, steel, M6/M8

100% of the produced ESD e-chains® are checked for their continuous conductivity from one end to the other

Conductivity of igus®® products made from igumid® ESD

In contrast to temporarily applied conductive surface coatings or volatile incorporated antistatic agents, the additives used allow long-term, permanent and maintenance-free conductivity. To ensure conductivity, however, it is not enough for the individual components of an e-chain® to have conductivity; the entire e-chain® must have continuous conductivity from one end to the other. All products in this catalogue are optimised in this respect and the continuous conductivity is measured and documented by a 100% test before delivery.

Only e-chain® that have passed this test are subsequently labelled with the test seal and delivered. The colour of the triflex® R chains is a special feature, as they are not slate grey (≈RAL7015) but still black, similar to ≈RAL9004. Unfortunately, this makes it somewhat more difficult to distinguish them from standard materials. However, this is clearly defined by the material stamp.

Consulting

I look forward to answering your questions

Dieter Reitz+49 2203 9649 7070Write e-mail

Shipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Friday: 8 am – 5 pm