Change Language :

Dosing robot

Dosing application in animal feed production

Efficiency and automation play an important role in industry. In this case, it was a question of scaling up production, as the employees were unable to increase production due to the manual processes. What was previously controlled by individual filling hoppers is now handled by a large tank and a hose.

- Automated feeding of the raw mass

- Compliance with constant output quantities

- Elimination of tedious manual processes

- cost-effective dosing processes through the use of Low Cost Automationsolutions

Dosing application in production

Fast and cost-effective automation of a dispensing application. The gantry cell is equipped with all the necessary components for standard tasks to minimise the effort involved in automation. The video shows the setting of glue dots with a dispenser

- Automated feeding of the liquid

- Uniform dosing of the liquid

- Reduction of manual, error-prone processes

- cost-effective dosing processes through the use of Low Cost Automationsolutions

Dosing application in 3D printing

With this XXL 3D printer, plastic waste can be reused and printed into components for houses. The printing gantries set up in overseas containers process regranulated plastic waste directly on site. A spatial gantry robot with stepper motor technology was used.

- Large-volume printing of plastic components

- Precise adherence to nozzle positioning

- Sustainable production of components directly on site

- cost-effective dosing processes through the use of Low Cost Automationsolutions

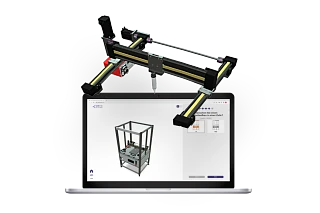

The dosing robot in 5 clicks

Configure automation solution online

- Save individual design effort

- Compatibility of all installed components guaranteed

- Minimal use of resources thanks to standardised systems

- Assemble robot application with 5 clicks and receive an immediate offer

Low Cost Automation Support

Do you need help with product selection or your project? You can reach us via these channels:

Consulting

I look forward to answering your questions

Shipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Friday: 8 am – 5 pm