Change Language :

Optimised writing flow with lubrication-free linear technology

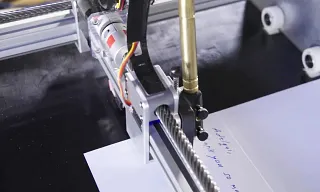

Handwriting robot works precisely, quietly and fail-safe thanks to dry-tech components

On behalf of Simply Noted, the US engineering firm Spline Product Development has realised a handwriting robot that is able to write cards in human handwriting to give messages a more personal touch. At the heart of the robot are our lubrication-free and maintenance-free linear guides and lead screws in the XY-axes, which ensure quiet operation, very high accuracy and reliability.

Profile

- What was needed? Linear guide, lead screw technology and motors for the XY-axis system

- Requirements: High precision, quietest possible operation, insensitivity to dust and dirt, long service life, no external lubrication

- Industry: Printing technology

- Success for the customer: Thanks to the use of lubrication-free and maintenance-free drylin linear guides, dryspin lead screw drives and electric stepper motors, the handwriting robots can work reliably in the end customer's warehouse without the dusty environment causing any loss of function. The components enable pin guidance with millimetre precision every second and score points with exceptionally quiet operation.

Products used

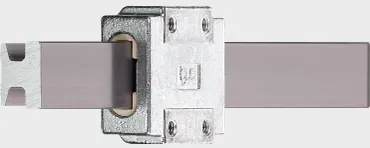

Miniature linear guide

drylin T miniature guide carriage with pretension, miniature guide rail TS-04

Lead screw drive

dryspin high helix lead screw with cylindrical lead screw nut DST-JSRM

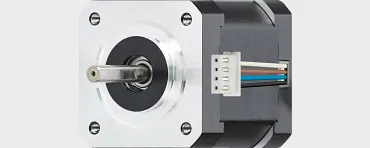

Motors