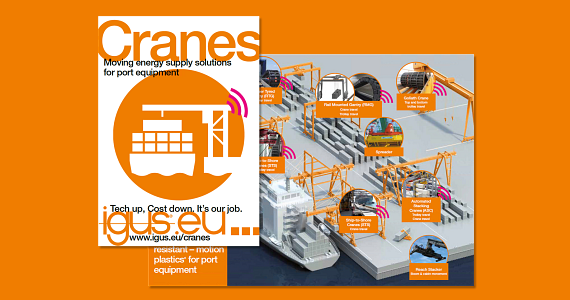

Energy chains, cables and heavy-duty bearings for port and intermodal cranes

Durable and networked products for long travels and high loads.

Why should I use an energy chain for cable guidance on the crane? With heavy cable loads, long periods of use and a wide variety of weather conditions, cable guidance in cranes must deliver top performance. The energy chain for port and intermodal cranes scores here with corrosion- and maintenance-free materials and a long service life.

Energy chains therefore prove to be particularly reliable cable guides in places where deadlines are tight but operational safety still has priority. The low-maintenance and quiet energy chains can prove their worth, especially compared to busbar systems, festoonings and motorised drums. Therefore, more than 10,000 ports already rely on the system.

On this page you will find an overview of our energy chains, cables, sensors as well as our maintenance-free and lubrication-free bearing technology for port and intermodal cranes.

Energy chains for cranes

Safe energy supply systems specifically for cranes: from medium travels on RTG or RMG cranes to high loads and travels of up to 1,000 metres.

Learn more

Cables for cranes

Tested, UL-certified and UV-resistant cables with a service life guarantee for particularly long travels and tight bend radii on cranes.

Learn more

Heavy-duty bearings for cranes

Lubrication- and maintenance-free heavy-duty and fibre composite plain bearings for the chassis and other crane bearing points subjected to high stress.

Learn more

Sensors for cranes

Prevent costly and time-consuming crane breakdowns thanks to networked products with sensors for condition monitoring and predictive maintenance.

Learn more

Energy chains for port cranes and intermodal cranes

Unplanned downtimes must never occur on the harbour or intermodal crane. This poses extreme demands on the cable guidance on the crane. If the trailing cables, the cable guided in an energy chain break, or if the cable guidance itself is defective, crane operation will inevitably come to a standstill.At the same time, these systems must be able to easily handle special loads over travels of sometimes more than 1,000m.

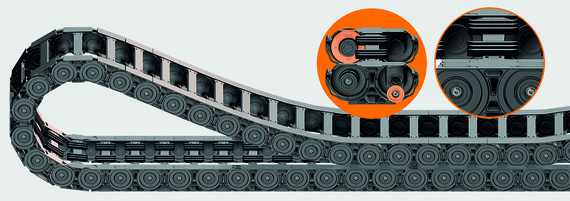

Such risks can be minimised with special energy chains for cranes. Thanks to the development of specialised solutions such as the roller energy chains even long travels are possible with low drive power. At the same time, this reduces wear and tear and maintenance costs. And thanks to optional sensors the safety of the chain and cable can be further increased.

P4HD - The e-chain with the longest service life

The further developed P4HD energy chain has been developed for the next generation of container cranes. The rol e-chain® is suitable for very long travels with high dynamics. Thanks to optional sensors (i.Sense and i.Cee), failures can be prevented before they happen.Find out more about the P4HD

Energy chain sample

Request a sample today: P4HD.56R

We want a 15-year service life for e-chains on cranes. This can be found in our development goals and the functional specifications for the new P4.1HD product range.

▶ Find out more here

P4.1 - The universal energy chain

The P4.1 is suitable for long travels of more than 1,000m and for high additional loads. Thanks to the possibility of an optional addition of sensors (i.Sense and i.Cee) for condition monitoring or predictive maintenance, the operational safety of the chain increases further.Find out more about the P4.1

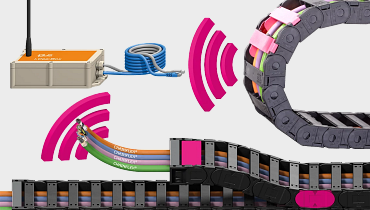

Sensors and accessories for energy chains

Sensors for energy chains

- Avoid costly failures with condition monitoring and predictive maintenance on the energy chain

- Measurement of push/pull forces, wear rates, acceleration and more

Learn more

How sensors strengthen STS cranes

In this exclusive case study at the crane operator EMO B.V., the use of sensors in STS cranes at the port of Rotterdam is presented. Thanks to the implementation of the sensors, the cranes now achieve running performances of up to 375,000km.Find out more here

Guide troughs

- Available in stainless steel or aluminium for seawater resistance to EN6060 and weight reduction

- Available as cost-effective and corrosion-free plastic trough

Find out more about guide troughs

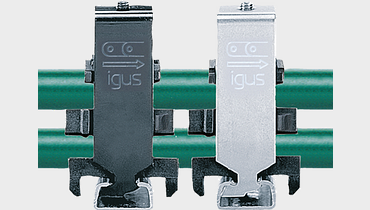

Clamps "chainfix CFXL"

- To relieve heavy-duty cables

- Strain relief even for hoses and cables with large diameters

- Easy to retrofit in the energy chain

Find out more about chainfix CFXL

Floating moving end

- To compensate for long travels

- Small, lightweight and cost-effective

- Compatible with isense EC.P

- Can be combined with various energy chains

Find out more about the floating moving end

The future of STS cranes and energy chains

Triple-E container ships and STS cranes

STS cranes are changing. Ever larger container ships (Triple-E) will require even larger cranes in the future. You can find out exactly how this affects STS cranes and energy chains here.

▶ Find out more here

Cables for port cranes and intermodal cranes

Cables that run in energy chains on the crane are subject to high mechanical loads, as are trailing cables. The long travels and tight bend radii inevitably lead to cable stress. For this reason, we test our chainflex cables in 700 daily tests in our in-house test laboratory. This allows us to issue a four-year guarantee on all cables. Incidentally, all of our TPE cables come with UL approval and are UV-resistant.chainflex control cables CF9 and CF10

In our range of control cables, we offer the strength that is required for long travels on cranes thanks to various numbers of cores, diameters and outer jacket materials.Discover control cable CF9 | Discover control cable CF10

Discover all control cables

chainflex motor cables CF37/38, CF330/340

Motor cables must also always move reliably and without failure. For example, when supplying the hoist on crane systems over long travels, with high mechanical stress and outdoor temperatures of -40° to +50°.Discover CF37 | Discover CF38 | Discover CF330 | Discover CF340

Discover all motor cables

chainflex fibre optic cable CFLG.LB

Available in various mechanical versions, you will always find the right fibre optic cable for your crane application. We deliver in different OM classes and fibre diameters.Discover fibre optic cable CFLG.LB

Discover all fibre optic cables

chainflex data cable CF11

The CF11 data cable can be used for long travels of more than 400m without any problems. Together with the UV resistance and high load limit, it is particularly suitable for outdoor applications such as on cranes.Discover data cable CF11

Discover all data cables

Your advantages with chainflex cables

UL certified

We also offer a UL cable (Underwriters Laboratories) for each chainflex cable type.UV-resistant

Suitable for outdoor applications: Our cables are all UV-resistant.Guarantee

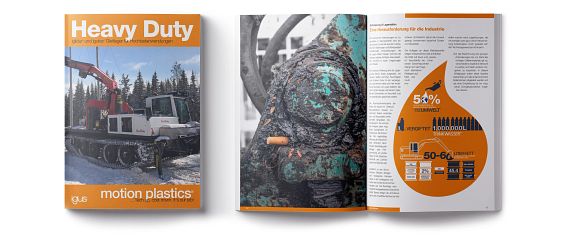

Thanks to our daily laboratory tests on chainflex cables we offer a four-year guarantee without hesitation.Heavy-duty bearings for port and intermodal cranes

igutex composite plain bearings consist of a robust fibreglass fabric outer layer and an inner layer optimised for optimum friction behaviour. This makes them suitable for high loads despite them being lubrication- and maintenance-free. Hence, maintenance costs and the risk of incorrect lubrication are avoided.Discover all heavy-duty bearings

Heavy-duty bearings in detail

Heavy-duty brochure

What materials are available for heavy-duty bearings? How do igutex bearings save on lubrication? And what do the load tests in the laboratory show? Find the answers to these and other questions in our Heavy-Duty Brochure.

▶ Find out more here

User report: lubrication-free bearings in RTG chassis

In the chassis, i.e. the "bogies", of their RTG cranes, Tan Cang Gantry rely on TX1 heavy-duty bearings from the igutex range. The TX1 bushings allow a surface pressure of up to 200MPa. This gives the engineers at Tan Cang Gantry more flexibility in the design. At the same time, the resistance on the shaft is minimised, which increases the service life.Go to user report

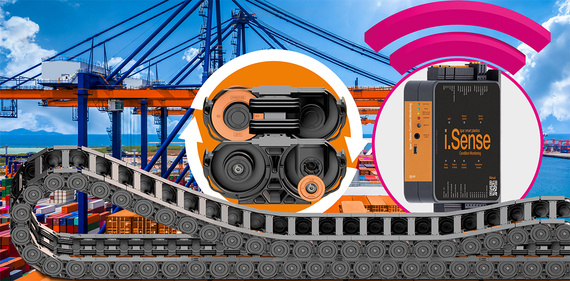

Sensors for port cranes and intermodal cranes

Sensors on the energy chain or the cables on the crane ensure a high degree of safety and certainty, particularly over long travels. On large structures and long energy chains, a cable rupture or defect in the energy chain is not easy to find. Added to this is the pure maintenance time. Such failures can quickly become very expensive, especially in busy container terminals. With the i.Sense and i.Cee sensor technology for monitoring or predictive maintenance of chain or cables, such problems can be avoided.

i.Sense condition monitoring

i.Sense smart condition monitoring sensors are used to continuously monitor the operating condition of moving components. They can perform various functions, depending on the application. In energy chains, they are used to monitor push/pull forces (i.Sense EC.P) and to identify chain ruptures at an early stage (i.Sense EC.B).Find out more about i.Sense

i.Cee predictive maintenance

i.Cee sensors continuously measure the clearance between the pin and the hole in a chain link. Together with the movement data of the system, the expected remaining service life of an energy chain is determined. If necessary, a warning is then automatically issued to replace or repair the chain. The result: More safety, lower costs.Find out more about i.Cee

Application examples. Here customers trust in energy chains.

In the video, those in charge at the Port of Virginia explain why the port is using energy chains for its new STS cranes. After equipping eight STS cranes with e-chains in a project, maintenance costs were reduced to a minimum while durability increased. Or as Jeff Johnston, in charge of maintenance at the Port of Virginia, summarises:

"[...] Reliability, easy maintenance and peace of mind."

Jeff Johnston, Crane Maintenance Manager at Port of Virginia

Jeff Johnston, Crane Maintenance Manager at Port of Virginia

And many other success stories ...

STS, ASC, RTG, RMG, shipyard crane, indoor crane. Our energy chains can be used practically anywhere. We will show you what this can look like in concrete terms using selected success stories:User reports: Port and intermodal cranes

User reports: Indoor cranes

User reports: Shipyard cranes

User reports: Bulk handling cranes

▶ Find all success stories here

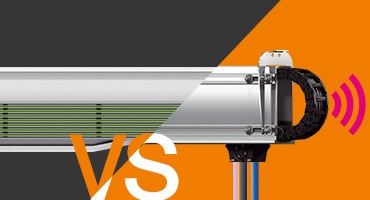

System comparison - e-chain vs. festooning, motor cable drum and busbar system

In wind and fluctuating temperatures, cables are protected and safely guided by energy chains. Downtimes are minimised as a result.

More about the festooning alternative

No slip ring on long travels. Guide all media safely in one system. Travels of up to 1,000 metres.

More about the motor cable drum alternative

Deliver data, energy, fluids and air safely in a single energy chain system. For narrow compact spaces and fast lane movement.

More about the busbar system alternative