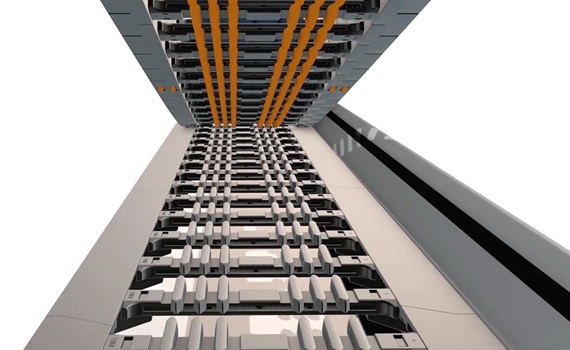

P4.1 rol e-chain®

The P4.1 rol e-chain series make it possible to increase plant safety and availability. There is a bearing point for a pivoting movement in every chain link connection. This point has now been re-equipped with maintenance-free high-performance polymer plain bearings, which more than double the service life.

- Longer service life - 375,000km running performance - due to maintenance-free tribo-polymer plain bearings in chain link connections.

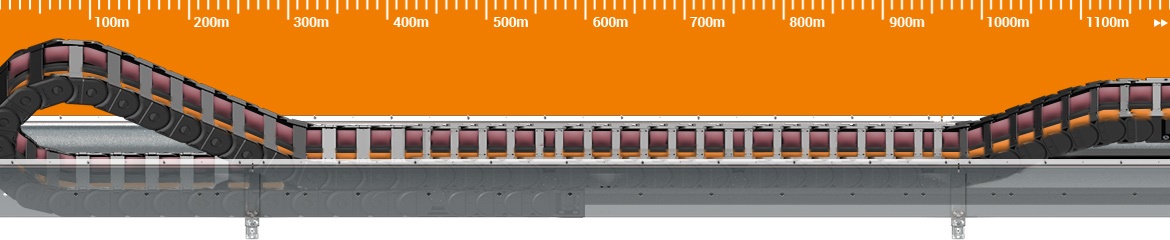

- Long travels more than 1,000m

- Speeds of more than 5 m/s

- Low vibration and noise due to a split profile roller

- Integration of sensors for intelligent condition monitoring

- Up to 36-month guarantee on energy chains and cables or the number of double strokes determined by the service life calculator.

Request P4.1 now

Your requirement

Increased plant reliability and availability

To meet the increased requirements of the new container ships such as the Triple E-class, new and larger STS cranes have to be built or existing ones converted. Crane availability and dependability requirements are also increasing. This affects the design and selection of the energy supply systems.Our offer

Latest generation P4.1 rol e-chain

To increase the availability and reliability of STS cranes, igus has developed the P4.1 rol e-chain. Here, tribologically optimised plain bearings ensure the lubrication-free mounting of the individual chain links. This more than doubles the service life of the chain. An optional sensor also enables predictive maintenance, which helps to further increase plant availability. Highly flexible cables from the chainflex product range complete the fail-safe solution for cranes and long travels. The P4.1 system is suitable for both trolley drive and longitudinal travel with travels of 1,000 metres and more.

Free white paper:Triple E-class container ships and the requirements of energy supply for STS cranes

Triple E-class container ships and the requirements of energy supply for STS cranes

This white paper deals with the following topics, amongst others:

- The challenge: cranes for Triple E-class container ships

- Crane availability and dependability requirements

- A comparison of energy and signal supply lines to the crane trolley (festooning, busbar systems and energy chains)

- Technological outlook: rol e-chains

Download white paper now

Service life comparison* igus rol e-chain generations

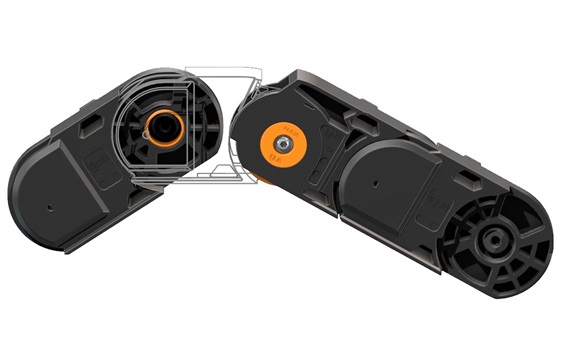

Special features of the rol energy chain P4.1

Coefficient of friction and drive power reduced

Due to the offset between upper run and lower run, the polymer rollers are not rolled over, but roll past each other to allow very smooth running. As a result, the coefficient of friction decreases and the drive power is reduced by 57 per cent.Longer service life

Equipped with maintenance-free plain bearings in each chain link, the service life of the energy chain is more than doubled.

Predictive maintenance

The new P4.1 can be fitted with an optional smart monitoring sensors. Thereby, when a wear limit is reached, a signal is issued to the igus i.Cee communication module, allowing maintenance of the rol e-chain® to be planned in advance.

P4.1 rol energy chain for long travels over 1,000m

Test for long travels

Request a project without obligation

Assembly instruction for P4.1 system

Easy and fast assembly as well as disassembly of the energy chain P4.1Joining:

- Compress chain links

- Screw in the screws with the screwdriver

- Install autoglide crossbars

- Dismantle autoglide crossbars

- Unscrew the screws with the screwdriver

- Separate chain links

Further information

Similar products

Previous rol energy chain P4 system

Evolution of the rol energy chain

Further information

Large selection of energy chains

Go to the energy chain shop