Experience the future with i.Cee: Predictive maintenance for igus energy supply systems

How can I save significantly on my maintenance costs with smart plastics from igus?

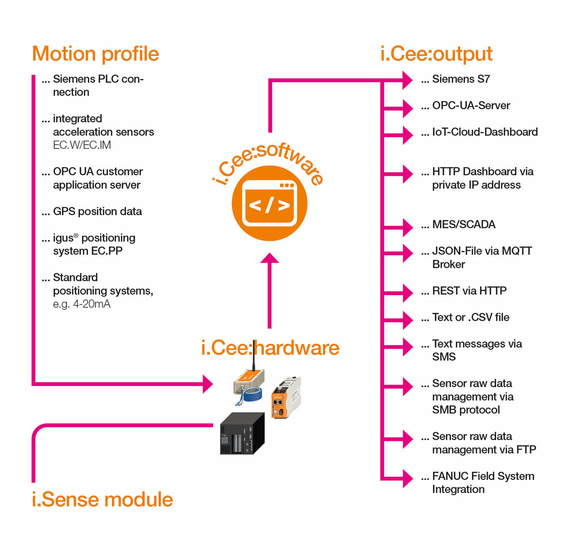

Only the intelligent networking of the individual components creates a solid basis for predictive maintenance concepts. At igus, we call our predictive maintenance system i.Cee. The central element of this system is the i.Cee software. It determines the maximum service life of igus products and the perfect time for servicing.

The advantages of i.Cee at a glance:

▲ Tech up

- Extension of the maximum service life

- Increase in overall system efficiency

- Integration into Industry 4.0/IIoT concepts

▼ Cost down

- Reduce maintenance costs through early warnings

- Eliminate unplanned downtime

- Decrease storage costs

Go direct to the i.Cee LIVE dashboard

Operation without surprises: smart energy chains for the most modern train washing station in Europe

Free case study

This case study talks about how CFL, Luxembourg's state railway company, uses several energy chains from igus® together with intelligent sensors from smart plastics to overcome numerous challenges:

- How exactly are failures prevented?

- Which components were to blame for the failure?

- How was the whole project approached and with what tools ?

- And how is it going at the moment?

Go to the PDF download

The i.Cee hardware

i.Cee EC.I

Excess clearance between a chain link's bolt and hole is a clear indication of the decreasing service life of an e-chain system®. The EC.I.SU.02 sensor measures this clearance in unambiguous percentage increments and sends them to the i.Cee:plus module. There, the remaining service life is calculated from movement data from the system's control system and, if necessary, a replacement recommendation is made.

i.Cee:plus II

More information about i.Cee:plus II

i.Cee individual

Send individual request

Sophisticated engineering made simple. Just 3 clicks to the smart complete set!

Discover complete sets from smart plastics here

You determine the manner of data transfer and access

Data transfer within your local corporate network (i.Cee:local) or on a secure cloud (i.Cee:cloud)

i.Cee:local

The options range from an energy chain within a single machine to a machine park and your own output interface.

i.Cee:cloud

How does predictive maintenance with i.Cee benefit you?

- Avoid expensive production losses caused by unplanned plant downtime

- Reduce maintenance and servicing costs

- Maximise the service life of the igus® components you are using

More about this in our FAQ on predictive maintenance

The igus® white paper on predictive maintenance

clarifies the distinction between condition monitoring and predictive maintenance

In our white paper, you can find out about the following:

- What igus® condition monitoring (i.Sense) means

- What igus® predictive maintenance (i.Cee) means

- What technology is behind both systems?

- What the two systems offer industrial energy supply?

Download whitepaper

More time for your own ideas ...

... thanks to less downtime with igus i.Cee

In automotive production, the line never stops. Collaborating robot arms for assembly and welding are in continuous use, as are all the components that supply them with energy and data. It is in just such environments that intelligent concepts such as predictive maintenance make the most sense. For a new Industry 4.0 project or for efficiency-driven retrofitting, our smart plastics solutions are available as universal modular systems and can be individually adapted to any system.Predictive maintenance in automotive production

smart plastics news 2023 ...

... experience now all smart plastics 2023 new products like the breakage monitoring for robot chains i.Sense TR.B or for the first time the new smart all-round service superwise right here:Industry 4.0: 2023 smart plastics News - overview