Intelligent breakage detection for e-chains

Unfortunate circumstances – not always a disaster thanks to i.Sense EC.B

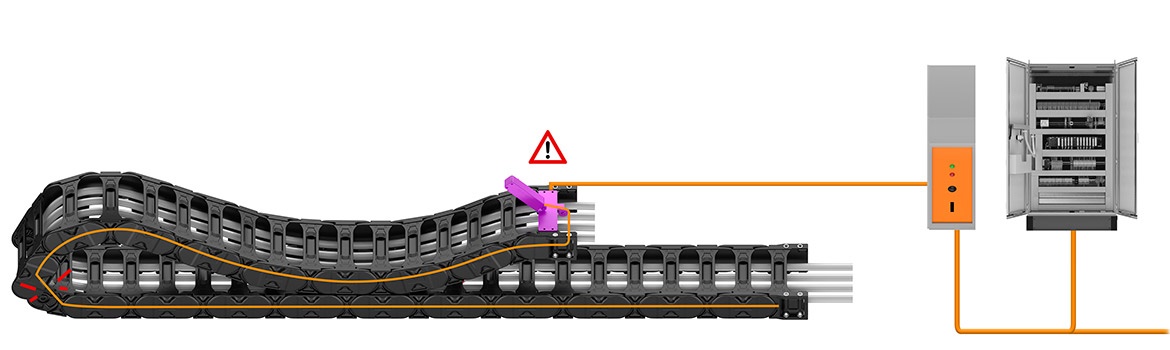

Links in e-chains® are made for tough continuous use. But forces may still sometimes overtax your e-chain®. When that happens, the EC.B sensor detects link breakage in your e-chain® immediately and, in the worst case, sends a notification right away. This allows you or your system to intervene directly, frequently preventing both additional damage (to the opposite chain link) and system failure.

Request a product sample

The advantages of i.Sense EC.B at a glance:

▲ Tech up

- Real-time condition data acquisition for the energy supply system

- Extend maximum service life

- Integration into Industry 4.0/IIoT concepts

▼ Cost down

- Avoid unplanned downtimes

- Prevent total failure when individual links break

- Reduce maintenance costs with early warnings

Information ...

Service, Help & FAQs

... Realise

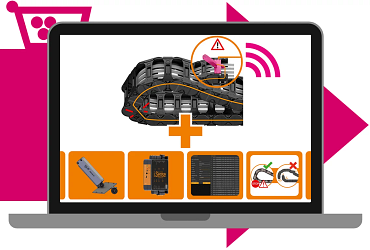

igus online shop

i.Sense EC.B intelligent breakage detection

Discover EC.B functionality in 82 seconds

- Module (EC = e-chain B = break detection) detects breaks in individual chain links

- A rope is passed through the e-chain and tightened to record any change in length and report it to the EC.B. sensor.

- This detects chain breaks, shuts down the system and prevents further damage

What are the technical components of i.Sense EC.B?

The technology for smart breakage detection in detail

Sensors

The sensor unit consists of a housing, a cable guide, a guide roller, a tension spring, and a 100mm travel measuring system. Starting at 35m of travel, a rope hoist sensor is used to measure the ropes's linear movement and convert the change in travel into an electrical signal. Chain widths greater than 350mm require two sensor units.The associated rope hoist is made of an extremely tear-resistant, non-elastic Kevlar fibre. The special separators guide the rope along the e-chain's neutral axis. Separators are mounted in every second chain link.

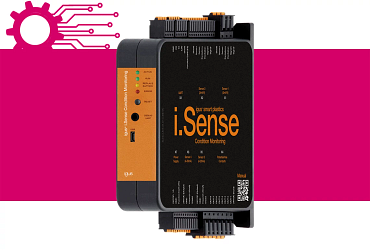

Evaluation module

Subsequently, all supplied push/pull force sensor data are continuously evaluated with the i.Sense Module II, which is mounted in the control cabinet of the system to be monitored and connected with chainflex cables. The module detects all movement anomalies immediately and transmits them directly to the user or the machine control system, such as Siemens PLC, via an NC contact. This new generation can connect up to four condition monitoring sensors at the same time with just one switch cabinet module, saving lots of space and costs.

Connectivity

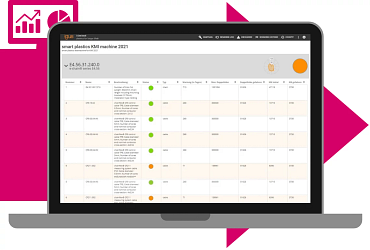

The module also offers many typical Industry 4.0 use cases, such as remote resetting or an SMS/e-mail alarm function. The i.Sense module offers other network options besides direct integration into the PLC plant control system to prevent total machine failure in an emergency.One is location-independent alerting with the optional SMS module. Another is that, in connection with an i.Cee module, all acquired sensor data can be output to an online dashboard.

How is the i.Sense EC.B sensor box mounted on the chain?

Download installation instructions

Download the operating instructions

View customer reference

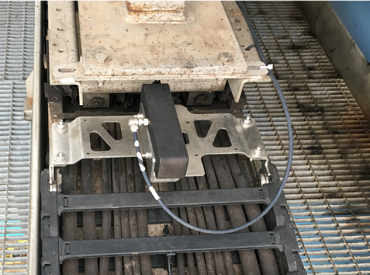

Final EC.B mounting on a container crane

Konstantin Schmer explains the system

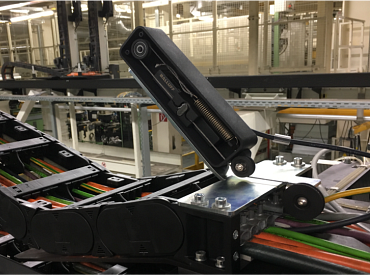

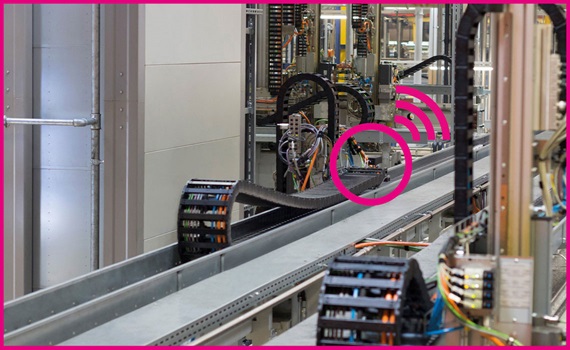

- The EC.B (EC = e-chain, B = break detection) module is installed on the e-chain's moving end

- Special mounting brackets allow the EC.B. sensor to be mounted on the moving end of the e-chain®

- Adding an EC.M (EC = e-chain, M = motion) sensor to the break detection system (EC.B) moves the system from mere condition monitoring to predictive maintenance. The additional measured values (speed, acceleration, and temperature) allow the system to calculate service life and display maintenance times

Intelligent breakage detection implemented successfully

Industry 4.0: i.Sense EC.B in practice

Wastewater treatment plants and wastewater operations |

Port and container cranes |

Conveyor and bulk handling

Double safety: abrasion and break monitoring

Double safety: abrasion and break monitoring

Innovation of the month at the engine plant of a German premium car manufacturer

Customer applications worldwide

Customer applications worldwide

To the application overview

When do I need a smart condition monitoring system like i.Sense EC.B?

When regular maintenance work requires complete production shutdown ...

When motion anomalies cannot be detected by humans in time ...

If plants or machines need to be monitored frequently or continuously ...

If energy supply system travels are difficult to access or view ...

If maintenance work poses a health or safety risk ...

If maintenance costs are to be reduced and service life extended ...

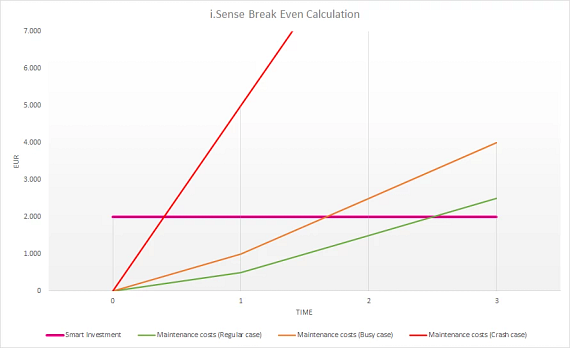

At what point does it pay to purchase i.Sense EC.B?

The financial benefits of safety systems are often difficult to assess, especially because the initial investment in a modern condition monitoring system increases costs instead of reducing them. So we performed a break-even analysis for the entire utilisation period based on practical experience in an automotive production hall.Given the average cost per working hour for all typical maintenance expenses in the German manufacturing industry (EUR 41.60), an i.Sense system reaches its benefit threshold in just the third year of use, even by a conservative estimate (regular case).

View the full break-even analysis

i.Sense EC.B as the basis for predictive maintenance

Always the optimum maintenance solution with igus smart plastics

For a solid foundation for predictive maintenance concepts, you need a smart network of individual condition monitoring systems, such as i.Sense EC.B. At igus, everything related to predictive maintenance falls under the term i.Cee. Similarly, i.Sense encompasses all condition monitoring systems.

The central element here is the i.Cee software, which, combined with i.Sense condition monitoring sensors on the energy chain, the plain bearing bushing, or a linear carriage, transform stock products into smart ones. This upgrade creates the capability of determining maximum service life and optimal maintenance intervals in real time based on real usage data.

The central element here is the i.Cee software, which, combined with i.Sense condition monitoring sensors on the energy chain, the plain bearing bushing, or a linear carriage, transform stock products into smart ones. This upgrade creates the capability of determining maximum service life and optimal maintenance intervals in real time based on real usage data.

More about predictive maintenance with smart plastics

General smart plastics overview

Insight into the entire igus Industry 4.0 product portfolio

Table of contents for this free brochure:

- Condition monitoring (i.Sense)

- Condition monitoring systems

- Advantages of condition monitoring systems

- Condition monitoring application examples

- Predictive maintenance (i.Cee)

- Systems for predictive maintenance

- Advantages of predictive maintenance systems

- Application examples for predictive maintenance

- Data flow in modern smart factory concepts

Download the smart plastics brochure

You are guaranteed personal advice

Do you have a crane or system for which you would like to monitor e-chain tensile forces to enhance system reliability?If so, feel free to contact me.

I am looking forward to your message!

► Request contact online

► Make an appointment

► Expert support by phone or with the video chat function

Contact us

3D CAD portal for smart plastics

Design intelligent energy chain systems faster. CAD models for all smart components.

Our intelligent e-chain systems are already reliably in use in hundreds of thousands of applications worldwide - from beverage machines and CNC machines to steel mills. Unsupported lengths can be bridged without problems and long travels are conceivable for the most varied of industries.To the 3D CAD portal