Weighing and inspection technology

From the filling of packaging units to the positioning of cameras and sensors

In addition to high-precision weighing, modern multihead weighers are also capable of dosing and counting. Cameras and sensors are then used to check the quality of the packaging. In both places, lubrication-free and maintenance-free linear and rotary bearing technology is required, that enables long service life and meets the high FDA requirements.Weighing technology

At the heart of multihead weighers are the load cells with their high-precision measurement recordings. In addition to weighing, modern systems are also capable of dosing and counting. Requirements for the bearing technology used for this purpose include high precision, freedom from lubricants, corrosion resistance and resistance to cleaning agents.Used products and application examples

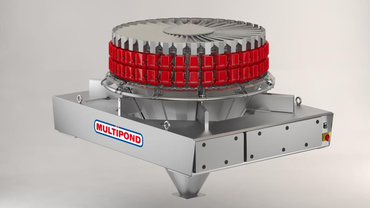

The example of a Multipond multihead weighing system from Atoma GmbH shows two areas of application in which igus bearing products are used. Above all, igubal pillow block bearings, iglidur plain bearings and drylin linear bearings were installed here:Ejection mechanism flap bearing

Filling/dosing

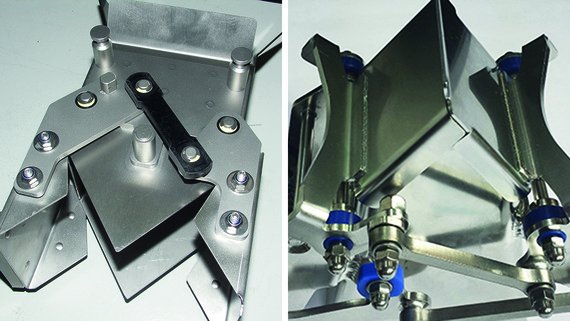

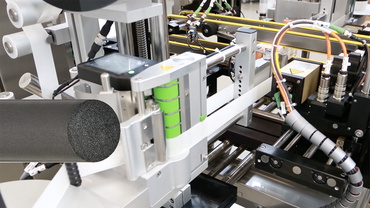

Ejection mechanism flap bearing

iglidur plain bearings are used in the ejection mechanism of the containers. A single iglidur material is used universally for all weighing systems, which covers a wide temperature spectrum, is electrically conductive and meets the high hygienic standards.

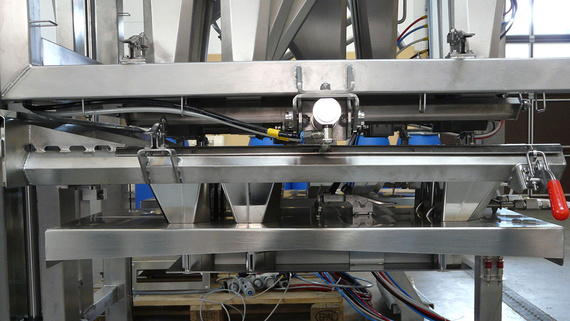

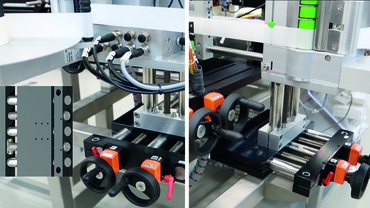

Filling / Dosing

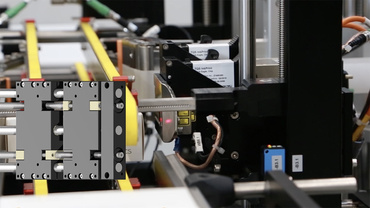

In the lowering screen drylin R linear bearings are used. The screen raises and lowers at a rapid rate and with a stroke of 40 millimetres above the packaging machine, enabling each individual packaging unit to be filled both quickly and precisely.Inspection technology

In inspection technology, products go through various inspection processes that require the use of cameras and sensors. To ensure that these are moved precisely and reliably, suitable linear bearing technology must be found. Lubrication-free and FDA-compliant bearings are required, particularly in food packaging. In addition, the focus is on robust systems with long service life.Used products and application examples

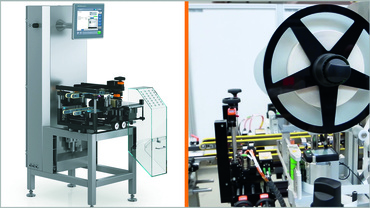

The TQS-SP TE system from Wipotec for testing and packaging products in folding boxes demonstrates the various requirements for bearing products within testing technology. In addition to format adjustments, the drylin lead screw linear systems used here are also used for the exact positioning of camera and sensor technology.1. Side and format adjustment

2. Transfer roller

3. Side and height adjustment

4. Pressure roller

5. Positioning of sensors

6. Guide rollers

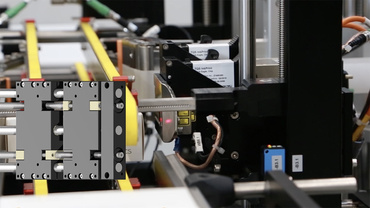

1. Side and format adjustment

drylin SHT linear systems with lead screw drive enable precise side and format adjustment by hand.

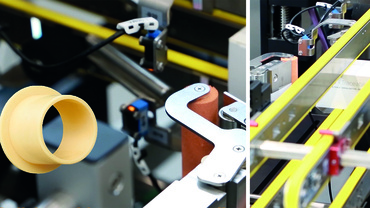

2. Transfer roller

A highly wear-resistant round bar made of iglidur JB is used as a transfer roller in the system. It also offers low coefficient of friction and operates without lubrication.

3. Side and height adjustment

The drylin lead screws used are robust and enable adjustment even under high loads and long stroke lengths.

4. Pressure roller

Several pressure rollers are used for product transport, which keep the products securely on track and ensure the short processing cycles. In the rollers, lubrication and maintenance-free plain bearings made of iglidur J prove themselves, even in continuous operation.

5. Positioning of sensors

In addition to the format adjustments of the testing and packaging unit, drylin SHT lead screw linear systems are also used for the adjustment of the sensors.

6. Guide rollers

And last but not least, the module from Wipotec also uses xiros ball bearings in the guide rollers. Like all components, they are also FDA-compliant.Customer application examples

Format adjustment in Krones test systems

Inspection technology machines from Krones rely on our plain bearings, slewing ring bearings, e-chains, gearbox solutions and linear axes for format adjustment.Go to user report

Pneumatic flap control system

In this weighing and filling system for food, the clevis joints are pneumatically controlled and thus actuate the flap system.

Testing and sorting plant

In this testing and sorting system, test parts are removed, measured and fed to various magazines with a vacuum gripper.

Filling and sealing machine

In addition to the high chemical resistance, the iglidur J plain bearings offer a maintenance-free dry operation in this application.And many more ...

Discover even more successful applications in the beverage, food and packaging industries.Discover more applications