Customised bearings for hygiene-sensitive multihead applications

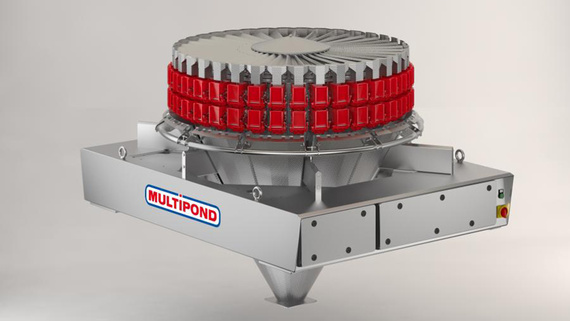

Newly developed storage technology is used in multihead weighers from Multipond.

With support from igus, Multipond, a world-renowned specialist for fully automated multihead weighers, can standardise the implemented bearing materials. Moreover, we have developed a customer-specific linear bearing housing for Multipond, which in terms of design meets the high demands of the food industry. When every gram counts, numerous food manufacturers rely on the automated multihead weighers of the Atoma GmbH in the Bavarian Waldkraiburg, which distributes its systems under the brand name Multipond.Profile

- What was needed: iglidur plain bearing, drylin linear bearing

- Requirements: High precision, freedom from lubricants, low wear, corrosion-free property, resistance to cleaning processes under superheated steam and high pressure as well as the use of aggressive media.

- Industry: Food industry

- Success for the customer: Whereas in the past the right material was selected for the specific area of application, today a single iglidur material is used that covers all specifications in terms of temperature spectrum, electrical conductivity and hygiene. Newly developed linear housings were also launched, made entirely of stainless steel. Multipond thus achieves improved corrosion resistance.

Problem

Numerous food manufacturers rely on the highly automated multi-head weighing systems from Atoma GmbH, which markets its systems under the brand name Multipond.The weighing systems work very accurately thanks to the high-precision load cells with measuring transducers. The most powerful Multipond weighers with 36 heads achieve more than 500 weighings per minute. They are mostly integrated directly into the fully automated production line. In addition to weighing, the newer models are also capable of dosing and counting.

In addition to ever higher performance and accuracy, hygienic design is also increasingly being taken into account. The weighing systems come into direct contact with the product and must therefore be lubricant-free. Depending on the area of application, specifications with regard to the temperature spectrum, electrical conductivity or hygiene or FDA requirements must also be fulfilled.

Rotative and linear bearing technology is used here at various points, which must meet these and other requirements:

For example, in the ejection mechanism of the containers after weighing. Bearings are needed here that can withstand the thorough cleaning processes in food production under superheated steam and high pressure as well as aggressive media.

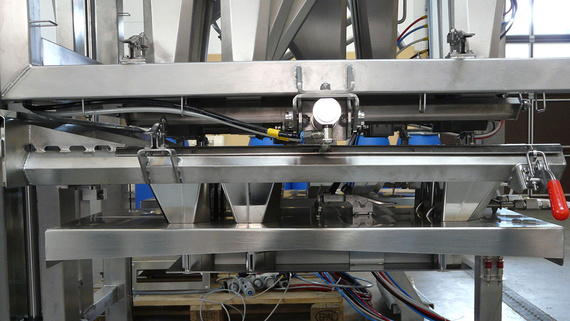

But Multipond is also increasingly supplying conveyor technology plus peripherals for integrating the weighing technology into the entire production line. For example, the transfer system was designed for a 36-head weigher for cereals. The lower part of this system, the so-called lowering screen, rises and falls at high cycle rate and with 40 millimetres stroke above the packaging machine and ensures the quick and precise filling of each packaging unit. As the lowering screen is only fixed on one side, high forces, including tilting moments, act on the linear bearing required for this purpose.

Solution

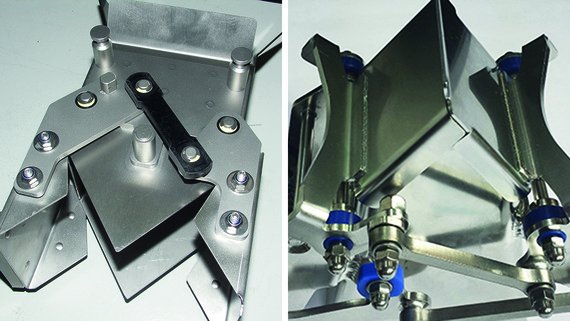

For the bearing components within the various plant sections, the Multipond designers opted for iglidur and drylin bearing technology:Ejection mechanism

For example, in the ejection mechanism of the containers iglidur plain bearings are used: The lubricant incorporated in the slidable high-performance polymer is not released into the environment. In addition, the plastic plain bearings are insensitive to the very thorough cleaning processes. Whereas the multi-component engineers used to select the right material for the specific application, today a single special iglidur material is used. This covers all three specifications – temperature spectrum, electrical conductivity and hygiene – and is therefore universally applicable. This enables Multipond to reduce the variety of bearing types to a third.

Filling system of the packaging unit

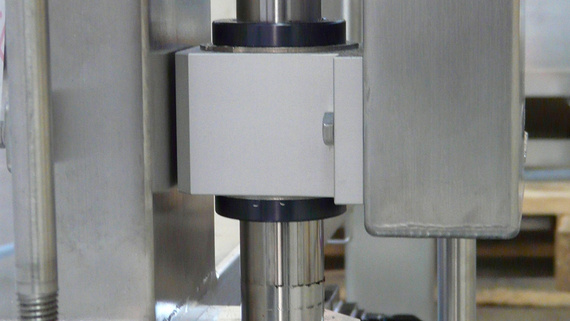

For the lower part of the Multipond system, the so-called lowering screen, linear bearings from the drylin R range are used. This raises and lowers in a fast cycle and with a stroke of 40 millimetres above the packaging machine and ensures that each individual packaging unit is filled both quickly and precisely. The housings of type RGAS allow an exact and wear-free shaft guidance via the proven iglidur liner.

Here, too, there is a current development project: a special type of RGAS linear housing was created for Multipond, which - apart from sliding elements, of course - is made entirely of stainless steel. The end pieces of the shafts are also made of stainless steel. Thus Multipond achieved an enhanced corrosion resistance in the frequent and thorough cleaning operations, to which such machines are subjected.

Andreas Peters, Group Manager New Design at Multipond