Maintenance-free iglidur® plain bearings made of plastic

Plain bearings are used to minimise direct contact e.g. between the shaft and the mount to prevent wear. Most bearings must be lubricated regularly to ensure fault-free operation. iglidur plain bearings do not require additional lubricants. They are therefore maintenance-free and represent a cost-effective alternative to metal plain bearings. They are available in various designs and in more than 10,000 sizes, here at Plain bearings online shop. The iglidur materials specially developed by igus enable a wide range of applications for our bearings in a wide variety of industries. For example, for use at high temperatures, contact with food or chemicals and under high loads.

What you will find on this page

The advantages of our plain bearings at a glance

Lubrication and maintenance-free

Due to the self-lubricating effect iglidur plastic bearings do not require any additional lubricants. How it works? Our iglidur materials contain solid lubricants, millions of which are contained in the material. These lubricants are released in tiny amounts and thus lubricate the bearing point. Therefore there are no problems with insufficient lubrication and only minimal maintenance requirements.

Cost-effective

Our self-lubricating plain bearings reduce your maintenance costs and completely save additional expenses for lubricants - with no minimum order quantity up to high volume. Our plastic plain bushes are up to 89% more cost-effective than plain bearings made of steel or bronze.Example: €2.37/piece versus €0.25/piece

Composite bearing steel/PTFE, size 2020 against iglidur MSM-2023-20

(Price for a purchase quantity of 100 pieces)

Calculate the service life

With the help of our free online tool you can calculate the service life of our plastic plain bearings for your application.How it works?

Our products are thoroughly tested in the test laboratory and the wear results are documented in our database. This data is then integrated in our online tool for service life calculation.

Available from 24 hours

We ship worldwide from over 73 countries to keep delivery times as short as possible for you.The most comprehensive product range for you:

- 10,000 installation sizes from stock

- Special parts according to your specifications

- Shipping within 24hrs

- No minimum order

- No minimum quantity

Resistant to chemicals and media

Our range includes a variety of different slide bearing plastics, which are e. g. characterised by high chemical or temperature resistance. Daily cleaning with aggressive cleaning agents and high pressure are therefore not a problem, since plastic bearing bushes from igus do not require any additional lubricants that would otherwise be washed out during cleaning.

Suitable for high loads

Our plastic plain bearing bushes are used e. g., in construction and agricultural machinery. In both cases, very robust plain bearing materials are required that can withstand not only dirt but also high loads. For this purpose, we offer on the one hand self-lubricating plain bearings made from our iglidur materials and for exceptionally demanding cases igutex plain bearings, which are reinforced with high-strength fibre-glass fabric.Try the new iglidur plain bearings online shop now

The new iglidur plain bearings shop includes our complete catalogue range. The new web shop also calculates prices and delivery times for customised plain bearings within seconds.

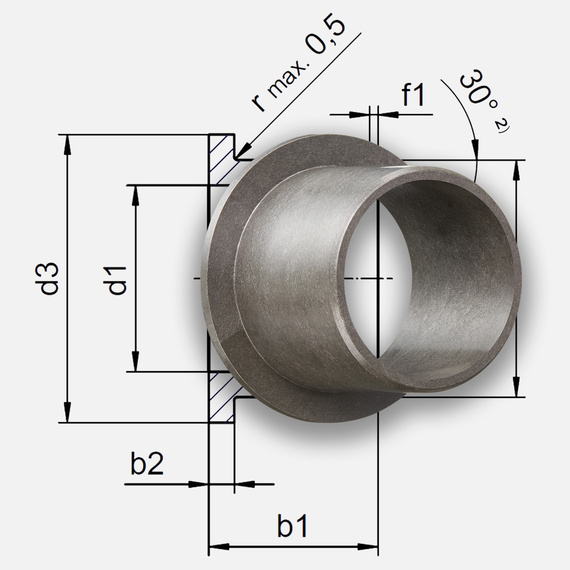

Bearings with flange

For shaft diameters Ø3 - Ø195mmTo the shop

Bearings

For shaft diameters Ø1.5 - Ø150mmTo the shop

Thrust washers

For axial bearingØ8 to Ø114mm

To the shop

Guide rings

For linear guidesØ4 to 80mm

To the shop

Clip bearings

For sheet metal solutionsØ8 to 25mm

To the shop

Two hole flange bearings

To screw onØ10 to 35mm

To the shop

This is where our plain bearings are used

Our maintenance-free and cost-effective plastic bearing bushes are problem solvers in a wide range of very diverse industries. This includes the automotive and food industries as well as medical technology. Our most important goal is always to get your applications in motion with our bearing bushes. Without any additional maintenance and lubrication of the bearing points. We will also find the right plastic bearings for your application.

Customer applications with iglidur plain bearings

Our plain bearing materials

You can find an overview of technical information and data sheets on our iglidur materials here and download the details. Find out more about the iglidur materialsPFAS and PTFE-free plain bearing bushes

Due to the current discussion about a PTFE ban, we have put together all the important information about PTFE in relation to our plain bearings. Here you will also find a list of all iglidur materials that do not contain PTFE.More information on PFAS in plain bearings

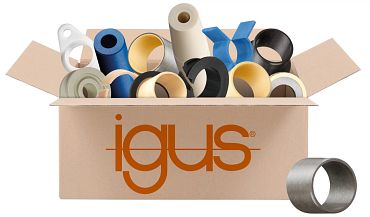

Free sample box

This sample box contains:

✅ 38 plastic bearings made from the most important iglidur materials

✅ Templates to find the perfect material for your application

✅ iglidur bearing technology catalogue

Request a free sample box now

Free white paper

In our free white papers, our plain bearing experts share their insights from practical experience as well as long-term research and development. In order to give you a knowledge advantage, we have prepared various topics of plain bearing technology for you.View the plain bearing white paper now

Special designs and drawing parts

In addition to our extensive standard range, we also offer custom-made products according to your specifications . There are various manufacturing processes to choose from, so that we can always select the best offer for you.Find out more about special and drawing parts

Plain bearing wiki

- What surface speeds can the igus plain bearing materials achieve?

- What is the coefficient of friction of igus bearing bushes?

- And what is the stick-slip effect?

Learn more

New igus plain bearing products

Discover our new products in the field of bearing technology. Customer enquiries constantly present us with challenges that often lead to the development of new products. Our goal is to always offer our customers the most cost-effective solution and to enable technical progress.To the new iglidur slide bearing products

Largest test laboratory in the industry

We carry out tests so that you don't have to. Find out how our iglidur plastic bearings are tested in the largest test laboratory in the industry. We also carry out individual customer tests here.Find out more about the plain bearing test laboratory

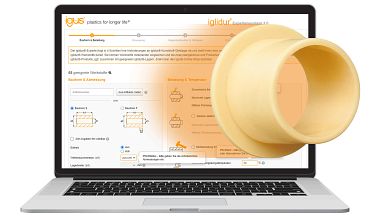

Free plain bearing online tool

Design iglidur plain bearings according to your needs. Choose your desired shape and material. With our tool, the iglidur Bearing Designer, you can also compare iglidur materials with each other and calculate their service life.Find out more about the iglidur Bearing Designer

Go directly to the online tool

Frequently asked questions about igus plastic plain bearings

How is the bearing clearance for plastic plain bearings determined?

Plain bearing bushes made of plastic require a certain amount of bearing clearance to compensate for various environmental factors. Some plastics absorb a relatively large amount of water or expand with increasing temperature. When this happens, the clearance decreases. If the clearance is dimensioned too small from the outset, it will jam. The shaft runs sluggishly, which can lead to altered haptics or machine performance. The bearing wears out faster. In the worst case, the bearing point even breaks down into its individual parts. It is therefore necessary to find a middle ground. As much bearing clearance as necessary, as minimal as possible. The lower the bearing clearance is to be set, the more precisely the environmental parameters should be taken into account and the more value should be placed on the most accurate and strict quality specifications possible.How are our self-lubricating plain bearings constructed?

iglidur plain bearings consist of three main components:1. Base polymers,

2. Fibres & fillers and

3. Solid lubricants.

The base polymers are decisive for the wear resistance of the iglidur materials. They ensure that the solid lubricants are not subjected to excessive surface pressure. Fibres and fillers reinforce the materials so that they can withstand high forces or edge loads and can be used under continuous stress. The solid lubricants lubricate the iglidur plastic plain bearings independently and thus reduce friction. They are distributed throughout the material in the form of microscopic particles.

All questions in the igus plain bearing FAQ