Filling and closing machines for tubular bags

Bag forming, filling and sealing machines pack products quickly and efficiently into pouches - whether food, pharmaceutical or non-food products.

Lubrication-free and low-maintenance motion plastics are the problem solvers in these machines at many points, e.g. in the drive of the sealing bars, in the bag folder or in the format adjustment of the bag width.

Lubrication-free and low-maintenance motion plastics are the problem solvers in these machines at many points, e.g. in the drive of the sealing bars, in the bag folder or in the format adjustment of the bag width.

Order a free sample box for the packaging industry

Overview of the bag forming, filling and sealing machines and products used

Vertical bag forming, filling and sealing machines (VFFS)

Bag forming, filling, and sealing machines quickly pack products, from food to pharmaceuticals to non-food products.Installed vertically, they can also be used in tight spaces. Lubrication-free, low-maintenance bearing components such as profile rail systems or lead screw linear systems are used in these machines at different stations.

Used products and application examples

The bag packaging machine stations and the igus products used are shown below as examples. drylin profile guides, lead screw linear systems, and iglidur plastic plain bearings are used in such applications as sealing bar and bag folder and for bag width format adjustment.1. Product dosing

2. Lower film unwinding

3. Film path correction | web edge detector

4. Film guide

5. Cross-sealing tool (sealing bar)

6. Longitudinal sealing tool (sealing bar)

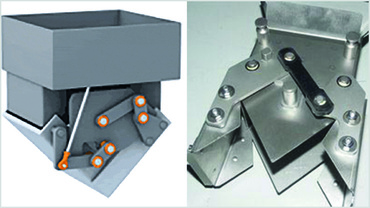

1. Product dosage

Wear-resistant iglidur J plain bearings and igubal spherical bearings requiring no lubrication or maintenance are used in the flap bearings to ensure reliable product dosing.

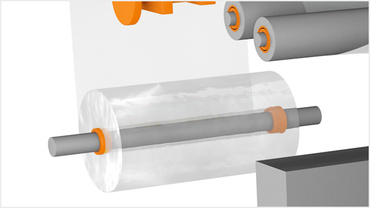

2. Bag-forming film unwinding

At the beginning of the packaging process, xiros ball bearings allow safe, durable unwinding of the bag-forming film. They enable maximum operating performance in continuous operation.

3. Film path correction | web edge detector

Format adjustment for film path correction is performed by maintenance-free drylin lead screw technology and drylin linear systems. drylin linear guides guide the sensors for checking the print mark and the web edge.

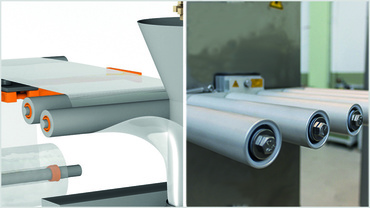

4. Film guide

xiros plastic ball bearings are often a cost-effective alternative to metal ball bearings. They operate without lubrication, are corrosion-resistant, and generate little noise.

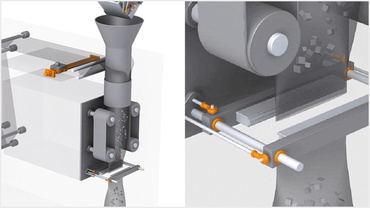

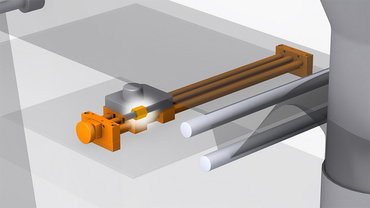

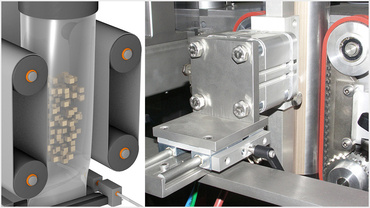

5. Cross-sealing tool (sealing bar)

Sealing bar support is maintained by drylin R liners combined with drylin R shaft guides and igubal rod ends, ensuring the highest operating performance.

6. Cross-sealing tool (sealing bar)

Sealing bar support is maintained by drylin R liners combined with drylin R shaft guides and igubal rod ends, ensuring the highest operating performance.Horizontal bag forming, filling and sealing machines (HFFS)

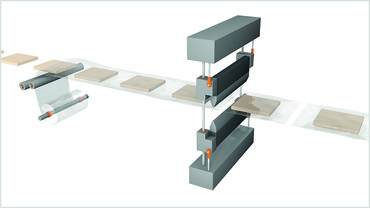

In horizontal bag forming, filling, and sealing machines, a wide variety of products such as food, pharmaceuticals, and non-food products are fed into pouches and packaged. Our linear products such as profile rail systems or lead screw modules are used at various stations in these plants to ensure a smooth packaging process.Used products and application examples

Bag packaging machine stations and the igus products they use are shown below as examples. drylin profile guides, lead screw linear systems, and iglidur plastic plain bearings are used in such applications as sealing bar and bag folder and for bag width format adjustment.

1. Positioning of the film roll

2. Format adjustment of the filling station

3. Positioning of the hole punch

4. Guiding of the bag folder

5. Format adjustment of the labeller

2. Format adjustment of the filling station

3. Positioning of the hole punch

4. Guiding of the bag folder

5. Format adjustment of the labeller

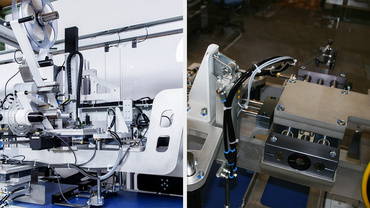

User report: Veprotech

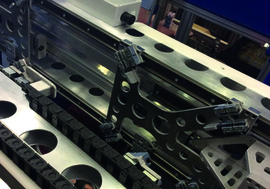

In the bag packaging machine from Veprotec, a total of 13 drylin SHT axes are used for format adjustments and positioning tasks.Go to complete user report

1. Positioning of the film roll

Manual positioning of the film roll is maintained by a drylin SHT-20-EWM axis with a driven carriage drylin® R.

2. Filling station format adjustment

The automated adjustment in the area of the filling station is carried out with a reverse drylin SHT lead screw linear system with flange-mounted NEMA 17 motor.

3. Positioning of the hole punch

A drylin linear system SHT-12-EWM with a driven carriage as well as a NEMA 17 stepper motor are used for automated positioning of the hole punch.

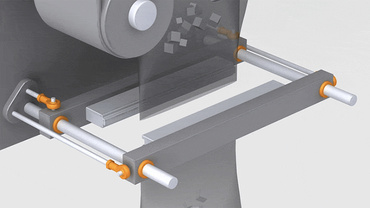

4. Guidance of the bag folder

drylin R linear plain bearings guide the movement (opposite directions) during the bag folding process.

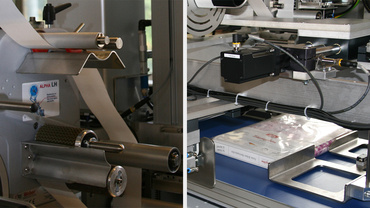

5. Format adjustment of the labeller

The automated format adjustment of the labeller is operated via a drylin SHT-20 with NEMA 23 motor.

Further application examples of our customers

Bag forming, filling and sealing machine

drylin linear bearings enable formatting in bag forming, filling and sealing machines without any lubrication or maintenance.Bag forming, filling and sealing machine: Hygienic design of the format adjustment

Film sealing device

In this bag forming, filling and sealing machine, drylin SLW lead screw linear modules enable adjustment of the film sealing unit without any lubrication or maintenance.Foil welding device