Film packaging: Technology from a single source

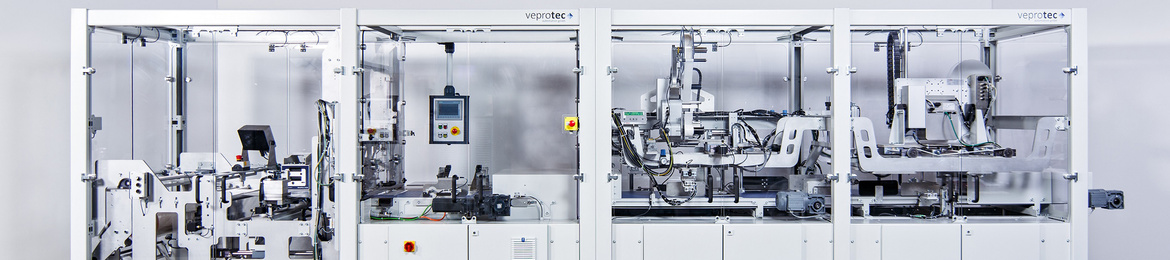

Lubrication-free SHT lead screw linear units automate this film packaging machine.

Packaging machines that are specially tailored to customer requirements - that is the business of Veprotec Automation GmbH in Dürnau. The start-up consistently banks on automation for more operational reliability as well as a modular concept for precisely tailored solutions. Our modular system in terms of linear technology is used for automated format changes.Profile

- What was needed: drylin SHT lead screw linear systems, drylin E lead screw stepper motors

- Requirements: For the positioning and format adjustments, a supplier was sought who could offer the complete range of products and provide a complete solution. They should be tough and durable.

- Industry: Packaging technology

- Success for the customer: 13 drylin SHT axes perform all positioning and adjustment tasks in the packaging machine. The linear systems are completely lubrication-free due to the use of polymer bearings and polymer nuts. The comprehensive modular system leaves nothing to be desired for an individual product composition.

Problem

The German packaging technology industry is booming. Innovations and international business are giving the industry a boost. This climate is ideal for Tobias Vester and Manuel Schuster. At the end of 2014, the two engineers took over the product range as well as the production hall of Weprotec GmbH Handling & Packaging Systems into the newly founded Veprotec Automation GmbH in Dürnau.The first machine type in the predecessor's product range that the two inventors tackled was a film packaging machine for bed linen. This machine is used to pack already folded bed linen in various formats in film. The bag packaging machine has a completely new design. Nothing remained as it was, as every assembly was completely redesigned. Only the functional principles have been adopted for the most part. They wanted to modernise the whole thing, and modularity was a big issue. The new system is equipped in such a way that various modules can be installed. Because not every customer wants the machine to have a hole punch or a labeller. Both can be selected as options, but the machine is designed in such a way that you can simply omit such parts. Veprotec has developed a completely modular basic frame, so to speak, which did not exist in this form before.

Veprotec packaging machines are equipped with a large number of format adjustment and positioning units. In this way, the various sizes of packaged goods can be covered or the film reel and hole punch can be positioned. The machine manufacturer was looking for a suitable solution to implement this.

Solution

Today, in the new construction of Schuster and Vester drylin SHT lead screw linear units from our comprehensive modular system play a very important role. The lubrication-free linear axes are driven either with trapezoidal thread, high helix thread or by toothed belt. There is always a suitable solution that ranges from plastic to stainless steel construction. The linear tables are lubrication-free due to the use of polymer bearings and polymer nuts and offer eight trapezoidal thread pitches and four high helix thread pitches. In addition, they can be installed both horizontally and vertically.For these reasons, a total of 13 drylin SHT axes are used in the bag packaging machine for format adjustments and positioning tasks. They fulfil various functions here:

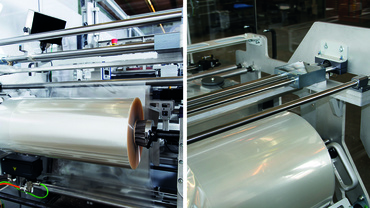

Positioning of the film reel

In the film depot section of the system, the manual positioning of the film reel is carried out by means of a drylin lead screw linear unit of the type SHT-20-EWM with a driven and a pulled along carriage as well as the torque support via a drylin floating bearing.

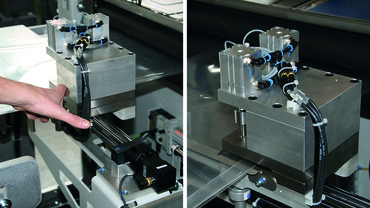

Positioning of the hole punch

And for the automated positioning of the hole punch, a drylin linear unit SHT-12-EWM with one driven and one travelling carriage and a NEMA 17 stepper motor is used.

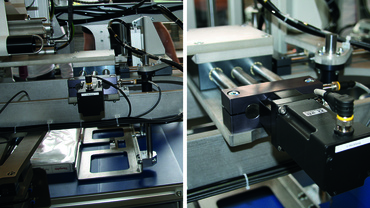

Format adjustment at the filling station

Unlike the positioning tasks, where Veprotec offers both manual and automated operation, the format adjustments work exclusively automatically. Thus, the adjustment in the area of the filling station of the bed linen is carried out with a reverse drylin SHT lead screw linear unit with flange-mounted NEMA 17 motor.

Format adjustment of labeller

And the automated labeller format adjustment is accomplished by a drylin SHT-20 with NEMA 23 motor.