motion plastics for automation in the catering industry

Automate services in restaurants and cafés with robotics, bearing technology, and e-chains

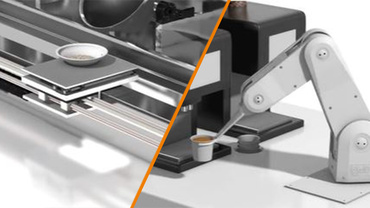

Automation in the catering industry, also known as kitchen automation or food service automation, can include all activities from selecting ingredients to preparing and serving food and drinks to customers. Room linear robots remove ingredients from the shelf, and cooking robots process them. Barista robots remove and serve the freshly prepared coffee. And delta robots assemble a burger with pick & place.

The rotary, pivoting, and linear movements in all of these processes are performed with bearings, gearboxes, and robotic components. These motion plastics, as they are called, are maintenance-free and can be implemented easily and cost-effectively.

The rotary, pivoting, and linear movements in all of these processes are performed with bearings, gearboxes, and robotic components. These motion plastics, as they are called, are maintenance-free and can be implemented easily and cost-effectively.

Request a customised sample now

What would you like to automate?

Removal and dispensing

How are ingredients safely and precisely prepared for further processing? How does the pastry come out of a compartment and reach the sales counter? One possible solution is linear robots, which, like storage and retrieval units in logistics, move to the correct position on a shelf, grip the product, and transport it to the dispensing position. The linear robot is lubricant-free and resistant to dirt, and its precision and maintenance-free nature also make a huge difference in this process.Buy a linear robot system or build your own

- Insensitive to dirt, since no lubrication is necessary

- Quick, simple assembly

- Up to 30kg load capacity, 0.5mm precision and 1.5m/s speed

▶ Information and shop: drylin linear robot

Articulated arm robot

- High flexibility: freely selectable end effectors

- Lightweight construction

- Return on Investment (ROI) after four to seven months

- Lubrication-free and resistant to dirt

More about robolink DCi

profile guides

- 14 rail profiles, 50 carriage versions

- 100% free of maintenance and lubrication

- Resistant to dirt, dust, and humidity

- Up to 40% more cost-effective than recirculating ball bearing guides

More about drylin W profile guides

Food-grade plain bearings

- Complies with FDA and EU regulations

- Good media-resistance

- Universal installation

More about iglidur® A181 plain bearings

Cables for moving applications

- such as the chainflex CF880 control cable

- Four-year guarantee

- All cables have been extensively tested in the laboratory

More about chainflex cables

Small energy chains

- Quick, easy filling

- Integrated brake for smooth, quiet operation

- Reduce installation space with small bend radius

More about E2.1 e-chains

Success stories: Removal and dispensing

robolink RL-DP for automated slush ice dispensing

As a highlight at the next trade show stand or in your restaurant, the robolink RL-DP can now also automatically dispense slush ice. The robot grips the cups with the help of a soft gripper. This automated output system does not require any programming knowledge or a great deal of time. The user-friendly igus Robot Control can be ordered optionally with the gripper arm robot. In advance you can program your application idea free of charge with the igus Robot Control software!

More about robolink DP

Automated beverage dispensing with the robolink bar robot

Need a little help behind the counter? Our robolink bar robot is not only a highlight for bar guests or visitors at your trade show stand, but also functions as a completely automated dispensing system. For this application, a robolink DP articulated arm robot was used together with the igus Robot Control system.

More about robolink DP

Food preparation

Food preparation is at the heart of kitchen automation. In addition to cooking robots, there are delta robots – robots that use pick & place to assemble the finished ingredients piece by piece. For example, a delta robot can make a burger made from buns, mustard and ketchup, a burger patty, cheese, and lettuce completely automatically.Compliance with hygiene guidelines is paramount here. Food must not be contaminated by machine components such as robot arms, bearings points, and gearboxes. motion plastics, which require no lubrication or maintenance, are the solution here. The system design is modular, so automation can be rapid and uncomplicated.

Delta robot for food use

- 660mm workspace diameter with 180mm of working height

- Self-lubricating, maintenance-free drylin ZLW toothed belt axes

- Ready to connect with stepper motors and a dryve D1 motor control system

▶ More information about delta robots

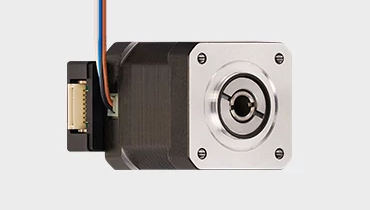

drylin stepper motors

- Powerful stepper motors

- Find the right drive for your application with the product finder

More about drylin E

robolink ReBeL robots

- The lightest cobot on the market

- Robots available with or without control system

- 2 kg payload incl. tool

More about the ReBeL cobot

Worm gear with turntable

- Dry operation thanks to tribologically optimised plastics

- Splash-proof and lightweight

- Large selection of accessories available

More about the Apiro turntable

Lead screws and nuts

- Completely lubrication-free and maintenance-free lead screw technology

- Low coefficients of friction and long service life

More about dryspin lead screw technology

Rod end with female thread

- Detectable rod end for the food industry: made of materials compliant with FDA regulations and EU 10/2011

- New design gives dirt no chance

Discover igubal KCRM now

Small energy chains

- Quick, easy filling

- Integrated brake for smooth, quiet operation

- Reduce installation space with small bend radii as low as 28mm

More about E2.1 e-chains

Success stories: Food preparation

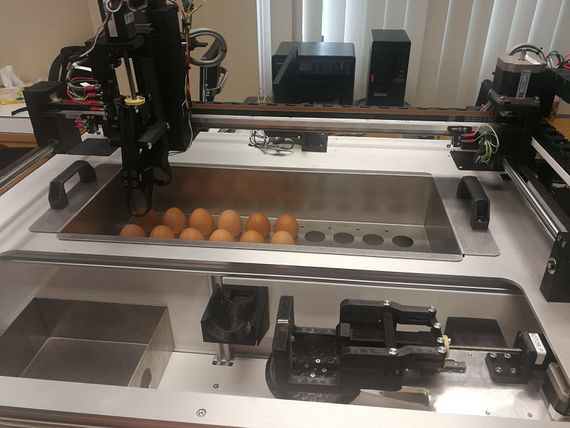

Modular and hygienic egg breaking machine

The company JSL Solution Pte Ltd has developed a machine for breaking half-boiled eggs. The machine can crack and distribute the eggs at the touch of a button, ensuring the freshness of the eggs. The egg is automatically transported from a tray to the cooking plate and separated. The empty egg shells are then transported to a separate compartment.

The maintenance-free and lubrication-free components are suitable for food applications with the highest hygiene requirements.

The maintenance-free and lubrication-free components are suitable for food applications with the highest hygiene requirements.

Find out more about this application

Lubrication-free linear axes in automated cocktail mixer

With the “CocktailAvenue”, a start-up company in Friedrichshafen has invented a completely new way of mixing cocktails: a machine takes over this task. Automation technology thus opens up a new, exotic area of application. Also included: drive systems and energy chains from igus.

More about the application

Maintenance-free dosing of mixed drinks

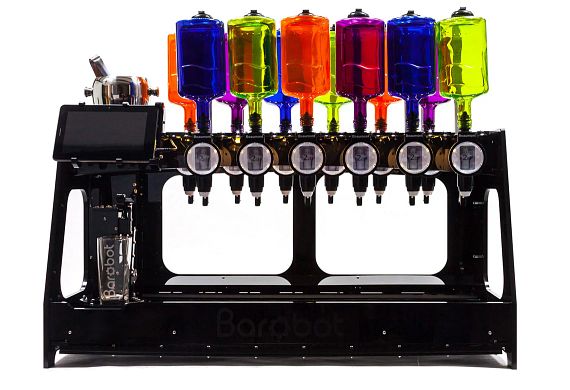

This participant is showing a completely new product in our manus competition: a fully automatic cocktail machine. At the touch of a button, “The Qube” mixes cocktails and long drinks from up to 12 bottles.

drylin spherical insert bearings in the bartender robot

A robot that replaces the bartender at a house party: that's the idea behind Barobot, developed by two inventors and founders of a Polish start-up. The machine can independently produce 1,000 cocktails from 12 bottles. For the transport carriage, which glides on a steel rod and moves the glass to the bottles, the developers were looking for a bearing with as little play as possible that is quiet, food-safe and cost-effective. Conventional metal ball bearings were not satisfactory. At igus, the perfect solution was found in drylin linear spherical insert bearing ...

More about the application

Transport and serving

The method of delivering a prepared meal the customer is determined primarily by the distance the product travels. A barista robot can be sufficient to transport a coffee mug from the machine to a nearby counter. Flexibility is just as important here as suitability for handling food. Longer distances in a restaurant may require such solutions as linear systems in which the food trays are systematically transported to a specific table.Barista robot: Build your own complete robot system or buy one

- High flexibility: Freely selectable end effectors for 2–5 degrees of freedom (DOF)

- Design and simulate online, including parts list

- With or without motor, with or without control system

▶ More information about the barista robot

robolink ReBeL robots

- The lightest cobot on the market

- Robots available with or without control system

- 2 kg payload incl. tool

More about the ReBeL cobot

drylin ZLW 7th axis for robot

- Flexible robot use instead of locking kinematics

- Adapter kit incl. Preparation of suitable e-chain systems

- Integration into the igus Robot Control

More about drylin ZLW

Gearboxes with stepper motors

- Move loads quickly

- Addition to the Apiro modular gearbox system

- Cost-effective, precise stepper motors

More about Apiro with stepper motor

Ball bearings

- such as the xiros B180 radial deep groove ball bearing

- lubrication-free, lightweight, and low-maintenance

- Low-friction, hygienic dry operation

More information on xiros ball bearings

Harnessed energy supply systems

- Ready-to-connect modules

- Pre-assembled directly by the manufacturer

- Optimise transport & assembly

More about readychain energy chains

Success stories: Transport and serving

robolink RL-DP operates a coffee machine with touch display

New from our customer testing area: for a customer application, a 5-axis robot robolink RL-DP was used to operate a coffee machine as a test. The challenge was not only transporting coffee cups to the machine, but also operating the coffee machine's touch display.

Overview of the customer testing area and other services

Fully automatic barista system mounted maintenance-free with iglidur PRT

If you cannot find an experienced barista, MyAppCafé has the answer: a fully automatic coffee robot that individually prepares top-quality coffee in seconds. A core element of this machine is the removal unit and its bearing support. This is where an igus PRT-04 slewing ring bearing is used. It ensures smooth movement and years of maintenance-free operation.

Find out more about this application

RBTX — The online platform for robotics components

The RBTX platform brings users and suppliers of low-cost robotics components together quickly and easily. Users can find gantries, robot arms, end effectors, camera modules, control systems and much more centrally in one place - and can find individual components or assemble entire robots.

At the same time, providers of robotics components can market their products to a wider audience in a targeted and convenient way on the RBTX marketplace.

Go to the RBTX online platform

Tested in the test laboratory for use in the real world

All products are tested for wear and load capacity under real-life conditions in the igus test laboratory, the largest in the industry. The results are integrated into our service life calculation tools and allow precise durability predictions.Upon request, igus carries out customer tests to check product use under completely customised conditions.

More about the igus test laboratory

What are the most important regulations for food sector vending machine manufacturers? How can installation space be saved in the face of a growing product range? The igus blog features interesting articles on vending machinery.

Take a look now!