Energy supply systems for the powertrain production line

Long service life, predictable maintenance

The drive train production line has high machine precision and reliability requirements. The various stations, some of which have long routes, form a complex system with high dynamics. Damage to one machine or component has an impact on the entire production line. It is vital that production be is not disrupted or affected by maintenance downtime.On average, an engine comes off the assembly line every 14 seconds – in peak periods, more than 6,000 engines are produced every working day. This output can only be achieved with reliable components and a high degree of automation. With smart plastics, our products for predictive maintenance, unplanned failures and plant downtimes can be avoided.

Success stories

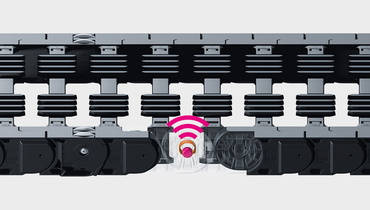

No unplanned outages due to intelligent energy chain monitoring

An Austrian engine manufacturer relies on our e-chains, which are equipped with smart plastics, in an indoor linear robot for handling engine blocks: sensors for abrasion and breakage monitoring detect wear and give an alarm in good time for repair or replacement. Unplanned plant downtimes and expensive production downtimes are avoided.

More about this application

Lubrication-free linear bearings in washing machines for motor components

In this industrial washing machine used to remove dirt from motor components before installation, conventional linear ball bearings failed. Due to the highly corrosive environment and the use of aggressive cleaning agents, our iglidur polymer bearings are now in use. They provide the required reliability and maintenance-free operation in the system.

More about this application

Suitable products

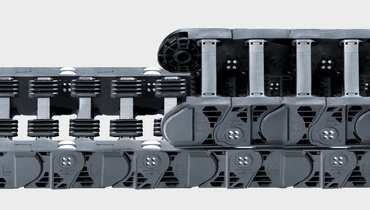

e-chains P4 series

- Save up to 57% drive force

- For long distances (up to 800m) and high additional loads (up to 30kg/m)

- Very smooth operation

More information about the P4

e-chain P4.1

- 375,000 km running performance due to maintenance-free tribopolymer plain bearings in the chain link connections

- For very long distances over 1,000m

Find out more about the P4.1

Predictive maintenance

- Extension of the maximum service life of chains and bearing technology

- Increase in overall system efficiency

- Integration into Industry 4.0 / IIoT concepts

Find out more about smart plastics

e-chain system E4Q

- Can be opened and closed without tools

- Optional noise dampeners for quieter operation

- Reduction in material leads to lighter weight

Learn more about the E4Q Series

Pre-assembled e-chain systems

- Eliminate storage costs for cables, e-chains and connectors

- Cut installation times by half

Find out more about readychain

chainflex drive cables

- 1,350 cables sold by the metre or 4,600 drive cables according to 24 manufacturer standards

- From stock, no cutting charges

More about our drive cables