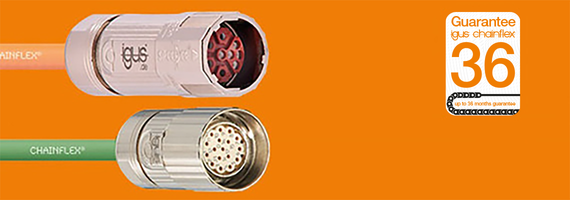

Flexible drive cables of the desired length with a guarantee for up to four years

Reliability in drive technology

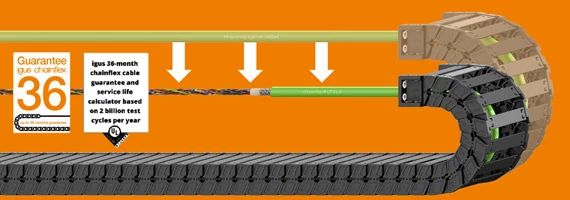

The is the largest moving cables test laboratory in the world. With 3,800m² of test area and over 800 tests running simultaneously on 64 systems, we achieve more than two billion double strokes per year to give you the highest-quality technology.The igus chainflex and readycable business units develop and produce cables that are sold by the metre with plug-in connectors for direct connection to electric drives. Electric drives create motion by converting electrical energy from the power grid or from a battery into mechanical energy. chainflex cables are thus the means of transport for electrical energy and set machines such as machine tools, robots, and handling machines in motion.

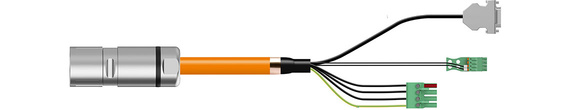

Harnessed

cables

Over 5,000 harnessed drive cables suitable for 30 manufacturer standards, in your required length

More about readycable drive cables

Highest quality in drive technology

In the area of drive technology, we have a large selection of high-end cables in our product portfolio. Very small bend radii in the energy chain in connection with long travels or extreme temperatures often pose major challenges for cables. Numerous tests in our test laboratory allow us to provide cables for the most demanding applications and extreme conditions that are of the highest quality and boast long service life.

Discover all the benefits of high-end drive cables

Single-cable solutions in drive technology

We take all these advantages into account in the CF220.UL.H (PVC jacket) and CF280.UL.H (PUR jacket) cable series. Here, the electrical wire/cross-section combination is constantly being expanded to be fully compatible with drives from various manufacturers, such as Beckhoff, SEW, and Siemens. We use the digit after the letter "H" in the part number to mark this affiliation to the manufacturer's requirement. The advantage for our customers is that, if the article number is identical from the "H" onwards, they can choose freely between PVC and PUR jackets without putting themselves at electrical risk. This can result in great savings.

The topic of drive cables is currently being considered in detail in our energy supply blog. There are especially many articles dealing with hybrid cables - Find out about the latest technical developments, directly from the producer!

Go to blog

Friedbert Dannenhauer, Deputy Head of Design at viastore on the relevance of igus online service life calculation

Customer applications for drive technology in use

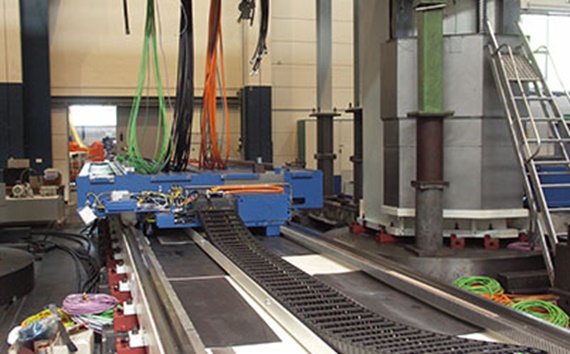

Measuring system cables for large scale machining centres

Good experience with cables for drive technology

CF113.D measuring system cables with PUR jacket and plug-in connectors are used in machining centres of the company WALDRICH COBURG GmbH. They have an improved cable and shield structure for a longer service life in energy chains. CF113.D cables are halogen-free and flame-retardant, and have UL and NFPA79.2012 certification.

WALDRICH COBURG GmbH

WALDRICH COBURG GmbH

Find out more

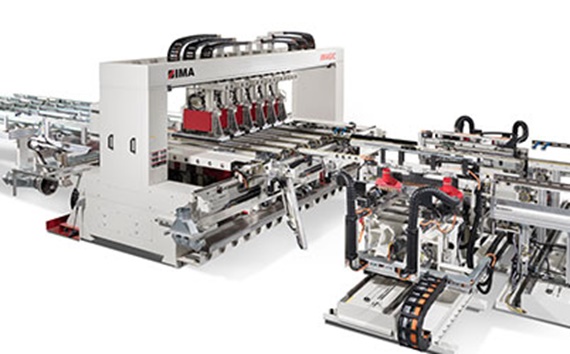

Automatic drilling machines

Hybrid cable used in a complex application

The hybrid cables of the chainflex® product range are being used in the new flexible IMAGIC flex drilling systems. chainflex® hybrid cables from igus® guarantee a long service life and dependability in highly dynamic applications.

IMA Klessmann GmbH

IMA Klessmann GmbH

Find out more

Machining centres

Reduce process costs and errors

Machine-tool manufacturer Hartford from Taiwan has equipped its robotic machining centres of the AERO series with igus® harnessed energy chain systems, which include energy chains and oil-resistant chainflex® cables.

Hartford

Hartford