Smart, reliable energy supply in the smallest of spaces

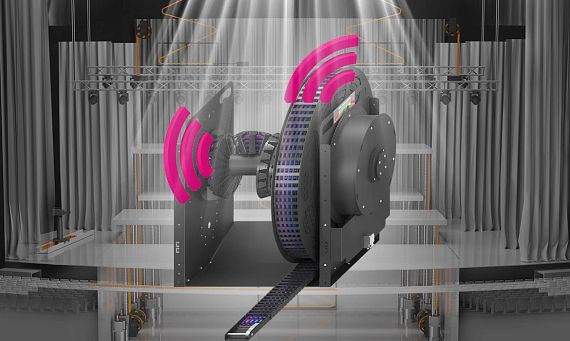

i.Sense ES.B: Intelligent break detection and function monitoring on the igus theatre e-spool guarantees reliable travel movements at all times

The new theatre e-spool now comes with various smart features: the force of the three springs included is monitored with a load cell sensor. If the force falls below the specified value, the user is prompted to replace the spring. When the specified value is exceeded, there is a blockage that must be removed.

A rotation sensor monitoring system can also be installed to count the drum revolutions and determine the position of the chain. As further protection to increase system safety, i.Sense EC.P could also be installed on the chain's moving end in the future for intelligent push/pull force monitoring.

A rotation sensor monitoring system can also be installed to count the drum revolutions and determine the position of the chain. As further protection to increase system safety, i.Sense EC.P could also be installed on the chain's moving end in the future for intelligent push/pull force monitoring.

Register for a free beta test

Tech up

- Increases system safety thanks to continuous function monitoring

- Extends maximum theatre e-spool® service life

- Measurement and display of the current extension length

- Provides remote access to real-time energy supply condition information

Cost down

- Avoid plant downtimes and expensive follow-up costs thanks to integrated breakage detection

- Reduce maintenance costs with immediate alerts in the event of e-spool anomalies

- Space-saving design without additional monitoring equipment

Proof

- Ongoing test series in the industry's largest test laboratory for dynamic power transmission systems

- Many successful energy management applications

with i.Sense condition monitoring

Sustainability

- Avoid resource-intensive emergency operations

- Have your energy chain recycled at the end of its life cycle with the igus® chainge recycling programme. No matter what manufacturer.

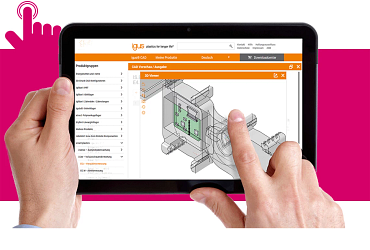

3D representation of the new theatre e-spool with spring force monitoring

The e-spool® system ...

... the slip-ring-free alternative to the cable drum

Safely guide many different cables in a confined space with e-spool. e-spool uniquely combines two different energy supply systems: one standard energy chain is guided by a roller, providing the correct length and tension of the energy supply system through an integrated spring. In the home position, the energy chain is completely rolled up to save space. The twisterband connects the roller with the shaft end block, serving as an interface to the supply side cables.Learn everything about the entire e-spool® system here

Intelligent condition monitoring implemented successfully

Industry 4.0: i.Sense in practice

Wastewater treatment plants and wastewater operations |

Port and container cranes |

Conveyor and bulk handling

"Less effort, greater availability"

"Less effort, greater availability"

Dipl.-Ing. Fabian Wilhelm, Project Manager for AOS Stade GmbH

Customer applications worldwide

Customer applications worldwide

To the application overview

When do I need a smart condition monitoring system like i.Sense?

When regular maintenance work requires complete production shutdown ...

When motion anomalies cannot be detected by humans in time ...

If plants or machines need to be monitored frequently or continuously ...

If energy supply system travels are difficult to access or view ...

If maintenance work poses a health or safety risk ...

If maintenance costs are to be reduced and service life extended ...

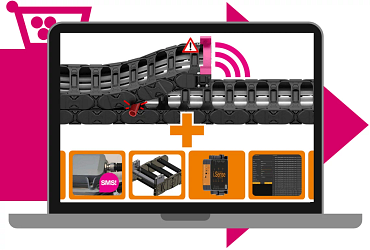

Smart machine data acquisition forms the basis for predictive maintenance concepts

Since the i.Sense Wonderbox is part of the smart plastics i.Sense condition monitoring system, all of its data can also be evaluated in the i.Cee control cabinet module. These data can then be used to digitally control the system's alarm and escalation management.

The i.Cee module can be integrated into predictive maintenance concepts in a number of ways, from preventive service management, which schedules regular maintenance depending on use, to location-independent fault management, which immediately reports any unforeseen change via various mobile channels. All information is collated in a modern dashboard, online or offline in the local network, depending on the customer's requirements.

Predictive maintenance

White paper on optimising overall equipment effectiveness (OEE)

Clarifies the distinction between condition monitoring and predictive maintenance

This free white paper explains:

- What igus® condition monitoring (i.Sense) means

- What igus® predictive maintenance (i.Cee) means

- What technology is behind both systems

- What the two systems offer industrial energy supply

Go to free download

24/7 push/pull force monitoring

i.Sense EC.P condition monitoring system

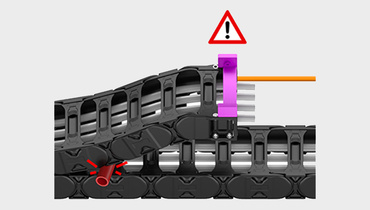

Additional protection for the energy chain is provided by the smart plastics i.Sense EC.P system (EC=e-chain P=pull force), which continuously measures the e-chain's push/pull forces. If force thresholds are exceeded, the sensor reports the issue and switches off the system to prevent expensive damage or total destruction.i.Sense EC.P condition monitoring

... Try it ...

3D data