10 years of success in handling systems

Polymer energy chains and bearings prove themselves in manipulators of HUSCH Handhabungstechnik

The handling systems of HUSCH Handhabungstechnik GmbH, which specialises in hand-held manipulators and load handling devices, stand for the highest demands of quality, reliability and flexibility. For over 10 years, our systems have been moving our plastic energy chains, but also linear and rotary bearing products. Used in the automotive industry, for example, they enable long service lives, robustness and freedom from maintenance.Profile

- What was needed: Plastic energy chains; iglidur plain bearings; PRT slewing ring bearings, drylin Q-square guides

- Requirements: All components must have a long service life, a high degree of robustness and be completely maintenance-free.

- Industry: Automotive industry

- Success for the customer: The systems operate long-term without failures and enjoy improved service life, but are also reliable and robust in harsh working environments and are completely free of lubrication and maintenance. Additionally, they ensure a high degree of quiet operation and ease of movement.

Problem

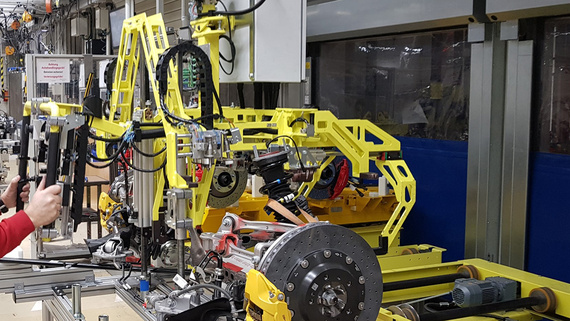

Under the motto "Lifting and moving with ease" the custom designed handling systems of HUSCH Handhabungstechnik GmbH, are used in a wide variety of industries, but above all in the automotive, food and glass industries, where they are used primarily in assembly, production and packaging.The various hand-guided telescopic, parallel or rope manipulators are designed, developed and produced on site in Höhenkirchen and are based - depending on the system - on a stand, a mobile base plate or a console for fixed or movable attachment to the ceiling.

Here, the solutions take on complex tasks for load guidance, positioning and relocation of products, for example in wheel assembly or in the harsh foundry environment. These have to be implemented in tight installation spaces and can involve movements around several axes.

HUSCH Handhabungstechnik always places the highest demands on quality, reliability and the greatest possible flexibility in its solutions. All components of the manipulators and load handling devices must have a long service life, a high degree of robustness and be completely maintenance-free.

Solution

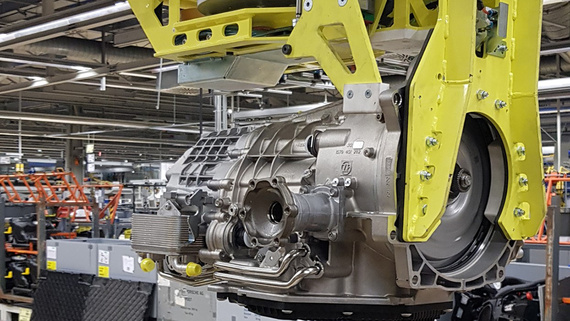

Today, our products and services help the customers of HUSCH Handhabungstechnik GmbH to produce high quality and durable equipment. For more than 10 years, a wide variety of e-chains as well as linear and rotary bearing elements have been used in the hand-held manipulators and load handling devices of the machine specialist.Therefore energy chains of the E2/000 series can be found in convertible top handling or on the telescopic manipulator, e-chains of the E2 mini type in the precise pick-up of drive axes or the triflex 3D energy chain on the highly dynamic manipulator for lifting or screwing applications in the underfloor area.

The bearing products used are mainly iglidur G and Z plain bearings, PRT slewing ring bearings but also rail systems such as drylin Q square guides.

The manufacturer opted for the systems because reduction in failtures snd the increasing service life, but also reliable in harsh working environments with complete freedom from lubrication and maintenance. In addition, they always ensure a high degree of quiet operation and ease of movement.

The CEO Lorenz Humpel also sees other advantages that speak in favour of the solutions: "igus is always 'up to date' scored highly with functionality and excellent CAD integration, even 10 years ago when we established the company. "We use the CAD models provided to us, or we use the online configurator."