Baling press with a long service life

Successfully in use for over a year: e-spool in a confined installation space in a baling press.

Machines that press materials into bales are used in many industries, e.g. in agriculture for hay bales. Each bundle has to be sealed during the pressing process. This process is linked to a rotation. As there is only limited space available for electrical cables and pneumatic hoses, they have to be connected to the applicator via e-chains. The e-spool system has now been in use for over a year.Profile

- What was needed: e-spool energy chain system

- Requirements: to seal bales, a solution had to be found for guiding the various electrical cables and pneumatic hoses in this baler in a small installation space.

- Industry: agriculture

- Success for the customer: the e-spool enables the necessary rotation in the application of up to around 455°. The customised solution works in the tightest of installation spaces and has done so without failure for a year now.

Discover all products for the agricultural industry

Problem

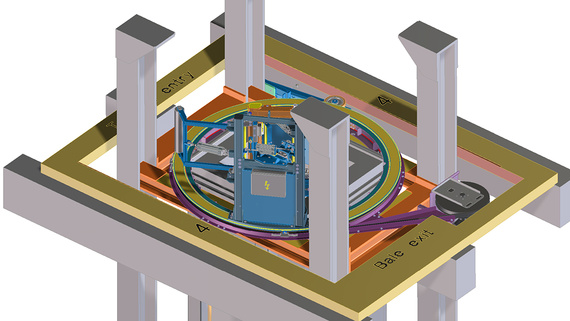

The Belgian manufacturer Valvan Baling Systems offers solutions for baling, among other things. As the name suggests, baling presses make it possible to bundle a wide variety of materials into compact bales. In agriculture, hay is compressed in trailers behind the tractor and at the same time each bundle is sealed before it is ejected from the baler onto the field. During sealing, a rotation takes place. For this, a solution had to be found for guiding the various electrical cables and pneumatic hoses in the machine in a small installation space.Solution

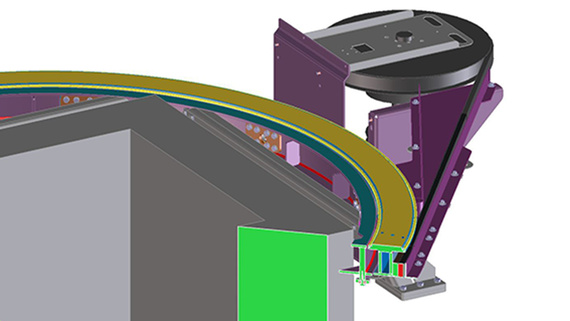

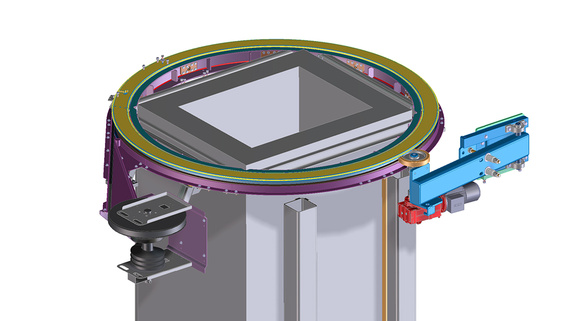

Today, a rotating ring is installed around the bale chamber and between the columns of the baler. The cable solution was realised with a plastic energy chain that unwinds together with the clockwise rotation of the ring as the hay bale is sealed. Once the hay bale has been ejected, the energy chain can be retracted again by turning the ring anti-clockwise. The rotation of the application exceeds 360° and reaches around 455°. Today, this is achieved by a e-spool, which was specially developed for such rotational movements. Thanks to a maximum energy chain width of 50mm, the customised solution for the manufacturer also manages to fit into the very limited installation space. The installation has been working reliably for more than a year.