Change Language :

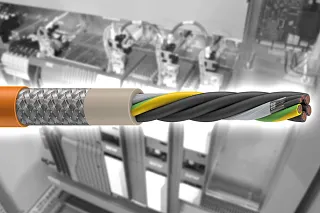

Servo cable for the energy chain

In electrical engineering, we refer to the connection cable for a servo drive as a servo cable. It connects the frequency converter to the motor. The fact that the frequency converter constitutes the energy supply for the motor means that we can adjust the speed by adjusting the shape of the voltage curve. This is normally done with pulse width modulation, which means spikes on the voltage curve. The servo cable must therefore have a higher voltage class (600V/1000V) and an overall shield. Because servo motors have a temperature sensor and/or brake, the cable includes two more shielded pairs for these functions.

Construction of servo cables

There are two different shields in the servo cable. There is the overall shield, which ensures the electromagnetic compatibility behaviour to the outside. This means that other components of the machine are not disturbed. Then, the pairs for the brake and temperature sensor are also shielded, which prevents interferences from the power lines from entering the control circuit of the frequency converter. These shields are designed differently depending on the mechanical stress. The higher the cable's mechanical stress level, the higher the quality of the shielding needs to be. In practice, this means that the shielding of our high-end cables has a significantly higher mechanical coverage of up to 90%. Furthermore, we use a special winding for the control pairs in the cable that not only has good electromagnetic compatibility specifications, but can also be processed very quickly thanks to its special design.

Why it doesn't always have to be PUR

PUR = chain cable and PVC = fixed installation. This is the common perception in the cable market. But it's not quite right. We at igus have tested the different outer jacket materials extensively for a long time in our laboratory and have come to the conclusion that PUR is a very good and flexible material, but does not necessarily always have to be used in the chain.

PVC has far better abrasion properties and is also more affordable. However, PUR is indispensable if the cable comes into contact with oil.

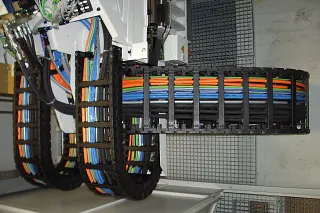

Servo cables in various machine tool applications

One area of application that describes the wide range of different possibilities for servo cables from the chainflex product range is that of a linked machine tool. Here, the machine is very narrow at various axes, so our CF270.UL.D cable series is generally the one chosen. The radius in the main axis is often larger, which allows for cost savings if the CF897 series is used. This series has longer stroke lengths in the stranding and is therefore optimised for larger bend radii. On the linear robot above the linked machines, e-chains are used in long travels. For the high dynamics and gliding use of the chain, this type of application requires an inner jacket, with which the CF27.UL is equipped. All series have a few things in common that are of fundamental importance for a machine tool. Every cable has UL approval, an oil-resistant outer jacket and the three-year guarantee with a clear statement regarding service life of up to 10 million double strokes. We work together and develop the most cost-effective solution with the help of the wide product range. Please feel free to contact our specialists immediately.

Haven't found the right one yet?

Do you already know our online tool?

Easy to find, select the right type, calculate service life and order online

Product finder

Find exactly the right cable quickly

Service life calculator

Calculate the service life of any chainflex cable

Copper surcharge calculator

Calculate the daily copper surcharge

Configurator for customised cables

Configure your customised cable in just 3 minutes

Are you still looking for an energy chain for your cable?

To the energy chains

... or everything ready harnessed as a readychain?

To the readychainConsulting

I look forward to answering your questions

Nils Jäger+49 2203 9649 9823Write e-mail

Shipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Friday: 8 am – 5 pm