Powerful toothed belt axis for keg transport in filling plants

At 700 kegs per hour, a robust and reliable linear axis should be found

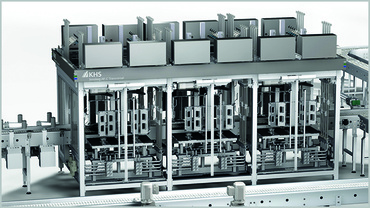

Normally, brewers have to decide between purchasing a cleaning and filling system for disposable kegs or one for re-usable kegs. The Innokeg AF-C Transversal of KHS can do both. This is possible due to the unique concept of transport and machining stations. One of our maintenance-free special linear axes with considerable dimensions is when a change between the stations is carried out.Profile

- What was needed: drylin ZLW linear axis, iglidur plain bearing, drylin linear bearing, isense condition monitoring technology

- Requirements: The KHS system has a capacity of 700 kegs per hour and therefore required a compact, robust, and powerful axis for keg handling. In addition, high availability and a long service life were required.

- Industry: Beverage industry

- Success for the customer: By using a large-dimension drylin ZLW toothed belt axis, it was possible to create a robust system that is appreciated by KHS customers for its flexibility. The linear axis also copes well with the absorption of high lateral forces during keg handling.

Discover all products for the beverage industry

Products used

Order a free sample

► Sample box for iglidur plain bearing technology► Sample box drylin W linear guides

Problem

With a wide range of filling and packaging machines as well as e. g. those used in the areas of cleaning, labelling and pasteurisation or within transport and inspection technology, KHS has a high market penetration worldwide and is continuously developing new machine concepts.The Innokeg AF-C Transversal developed by the company and ready for series production is a real innovation in filling technology.

The system is characterised by exceptional flexibility with regard to the inspection, cleaning and filling of kegs (Fig. 1). Changing between re-usable and disposable kegs does not require any conversion of the system, whereby up to 700 kegs can be handled per hour. This is enabled by the innovative machine layout: the processing stations are arranged transversally, i.e. on both sides next to the central conveyor belt, so that, if necessary, the kegs can simply be transported through the system to the filler, which is the last machine, without having to go through the entire cleaning process or individual steps. Three driven sliders per machining station (of which there are up to four) can be used to move them through the drylin system from the side of the belt into this station and out again.

In contrast to glass and PET bottles as well as cans, kegs are heavy containers with corresponding requirements regarding handling technology. One of the challenges for the design engineers of the Innokeg AF-C Transversal was to develop a compact, robust and high-performance axis for transversal keg handling.

The aim is to move kegs with a weight of two times 80 kilograms over a distance of 1,820 millimetres across the transport direction, and this at a speed of 1.5 m/s and with an acceleration of 2 m/s². The system has to work under the hygienic conditions of beverage filling in 24/7 operation with a very high degree of availability and a long service life.

Solution

drylin ZLW toothed-belt axis in conveyor technologyThe persons responsible for mechanical design analysed the market and examined the solutions proposed by different suppliers. In the end, the multifunctional drylin ZLW linear axis proposed by us convinced them (see Figs. 2 and 3 below). A good two metres long, 41 centimetres wide, 10 centimetres high and weighing 126 kilogrammes, it was supplied ready to install.

A total of four guide rails, two of which are used for parallel guidance, were assembled to create a compact system for KHS. This means that the three "thrust arms" (the middle one for sliding the kegs into the station, the two outer ones for moving them back onto the central conveyor belt) can be operated together on one shared linear axis.

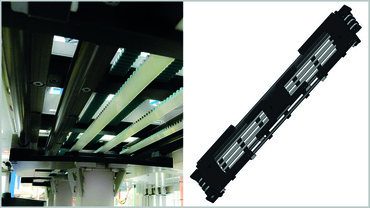

To adapt the guide length of the carriages to the high torques that occur when the kegs are pushed across, the carriages are arranged on two levels. They are moved by means of two centrally located toothed belts (Fig. 4 below). As a space-saving measure, the motors are accommodated in the extension of the deflection axis on both sides of the unit.

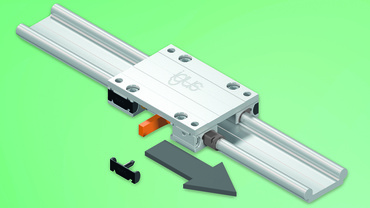

iglidur plain bearings on the axes

On all axes, plain bearings made of iglidur materials that need no external lubrication are used – an important aspect with regard to cleaning and filling under hygienic conditions. Moreover, an intelligently designed and easy to remove axial locating spigot enables fast replacement of the linear guide liners (Fig. 5 below).

drylin linear bearings in the lifting stations

In addition, linear bearings are used in many places in the Innokeg AF-C Transversal. The axes of the lifting stations, for example, are equipped with drylin stainless steel linear bearings (Fig. 6).

Condition monitoring for the plain bearing systems

For the near future, the use of isense technology to monitor the wear of the plain bearing systems within the framework of predictive maintenance is being considered at KHS. This can enhance the availability of the systems and increase the benefits to the customer.

Sebastian Eckes, design engineer at KHS