Smooth-running plastic bearings replace metal bearings in DMG machine tools

Trouble-free plastic bearings at Deckel Maho Gildemeister save at least 50% costs

The machine tools of Deckel Maho Seebach GmbH, a company of the Gildemeister group, are a household name in the trade. One prerequisite for the outstanding quality of the milling centres and production facilities from Thuringia, which are produced according to the latest technical standards, is not least the processing of high-quality materials, down to the smallest detail. Two years ago, for example, commercially available plain bearings made of Teflon-coated metal in the tool magazine chains were replaced by plastic bearings from Cologne-based igus GmbH. With complete success: the newly used material is not only more resistant and wear-free than the old one, but also up to 60 percent more cost-effective.Profile

- What was needed: iglidur-plastic-plain bearings, energy chains

- Requirements: Smooth running of the energy chains under high loads in the machines

- Industry: Machine tool manufacturing

- Success for the customer: Extensive laboratory tests for the replacement of the metal bearings led to the ideal product, the iglidur plain bearings, which maintain an almost constant sliding coefficient of friction over the entire service life, are maintenance-free and at the same time fetches a cost saving of at least 50%.

Discover all products for machine tools

Problem

As a company of the Gildemeister group, Deckel Maho Seebach GmbH in Thuringia occupies an outstanding position in the manufacture of machine tools. The machine builder's factory obtained its current impressive appearance in 2001, when a new production hall with a demonstration centre was added to the building complex. One year later, Deckel Maho received the Industrial Excellence Award as the best company in Germany and France.Deckel Maho currently employs around 450 people in Seebach, including 20 trainees, making it one of the largest employers in the region. Within the Gildemeister group, Deckel Maho operates largely independently.

In addition to the design and production departments, purchasing and sales are also located in Seebach. Universal milling machines, machine tools and production machines as well as travelling column machines are manufactured in Seebach at the highest quality level.

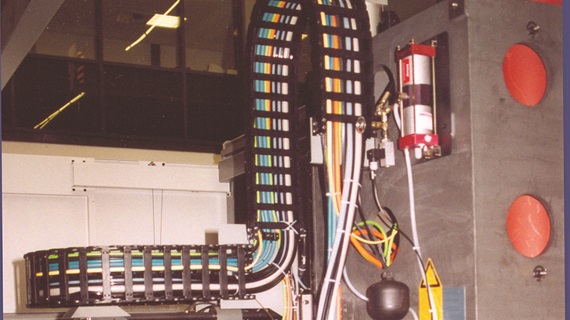

Not only do all the machines in the production area at Deckel Maho Seebach GmbH require a power supply, but a supply solution for the countless energy and control cables also had to be found for the indoor and gantry cranes for internal use. The machine tools, in which high loads act on the existing energy chains, must run very smoothly. Teflon-coated metal bearings were previously used here.

Solution

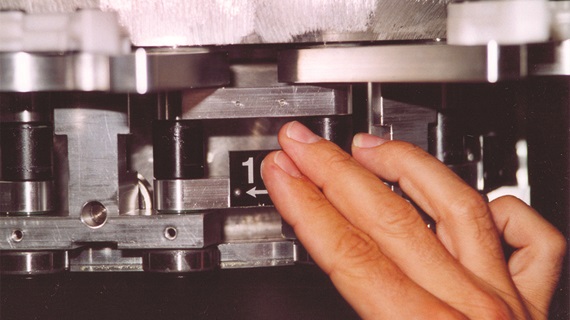

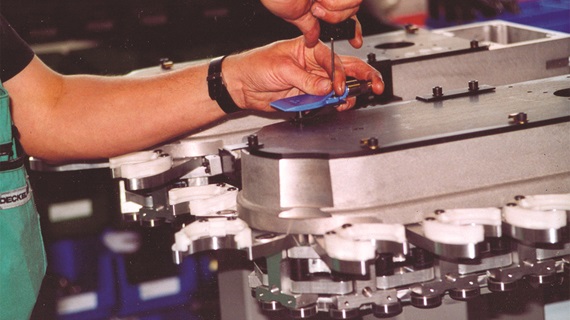

In all machines as well as in the internal indoor and gantry cranes , energy chains from igus are used.Chain-type holders are increasingly used in DMG machines to provide the various milling cutters, drills and other tools. For smooth running and trouble-free operation in the machine tools, iglidur plain bearings are now pressed into the chain links instead of the metal bearings previously used.

Michael Offner, the igus product manager in charge of machine tools, also examined, among other things, these tool magazine chains. In the process, he noticed that both the pivoting movement of the chain links of about 20 degrees and the load acting on the joints would make the use of plastic bearings reasonable. In such applications, plastic bearings have an advantage because the lubricants are firmly embedded in the material over the entire contact surface. As a result, they maintain an almost constant coefficient of surface friction over their entire service life, are maintenance-free and also represent a cost saving of at least 50 percent.

Extensive test and comparison series undertaken by igus with various plastic and metal bearings confirmed the statements regarding coefficient of friction, load capacity and wear for the standard material iglidur D. In addition, iglidur D is insensitive to chemicals and is characterised by low water absorption.

After the machine builder was initially sceptical about the plastic plain bearings, the final results of the test series led to a change of mind.

Jens Ebert, DMG developer and design engineer at Deckel Maho

Partnership expanded

Due to the positive experience with the plain bearings in the tool chains, Deckel Maho has now also switched to plastic bearings from igus in other applications - and not only in Seebach. Whether in use in the sliding doors of machine tool enclosures or other movable parts: Confidence in igus plastic bearings is growing, and new applications are constantly being explored.At present, research and tests with new materials for plain bearings are again underway in close cooperation between Deckel Maho and igus. Those responsible are expecting groundbreaking results from the findings, which should also be of the greatest interest for completely different industrial sectors. However, the aim and purpose of this joint project have so far been kept strictly confidential.