igus-icon-lupe

igus-icon-lupe

igus-icon-lupe

igus-icon-lupe

igus-icon-lupe

1 of 5

igus-icon-arrow-left

igus-icon-arrow-right

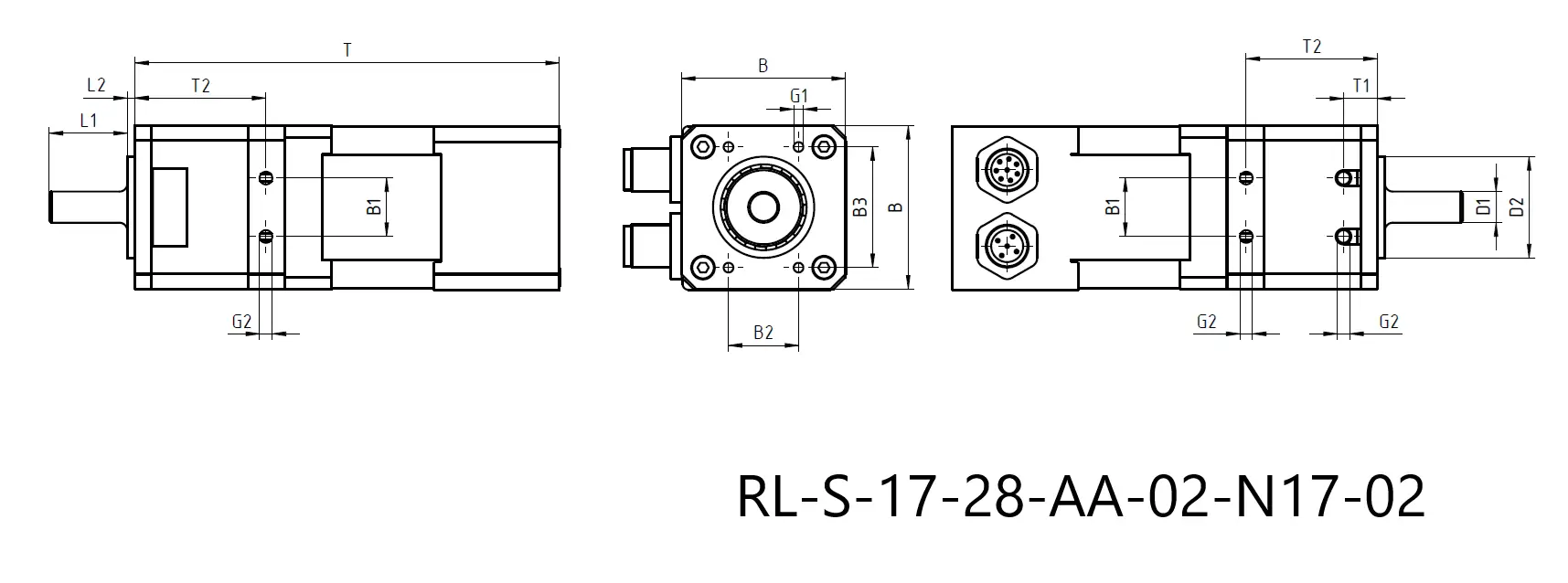

- Installation size: strain wave gear 17 with NEMA17/flange dimension 42mm

- Optional motor connections: stranded wire, connector, encoder and brake

- Available transmission ratio: 28:1

- Output torque: 4.0 Nm

igus-icon-lieferzeit-dotRL-S-17-28-AA-N17-00

with stranded wire