Corrosion-resistant and lubrication-free bearing technology for laboratory cooling systems

Around 10,000 units of blood are stored on 21 trays that can be moved with the help of our bearing technology.

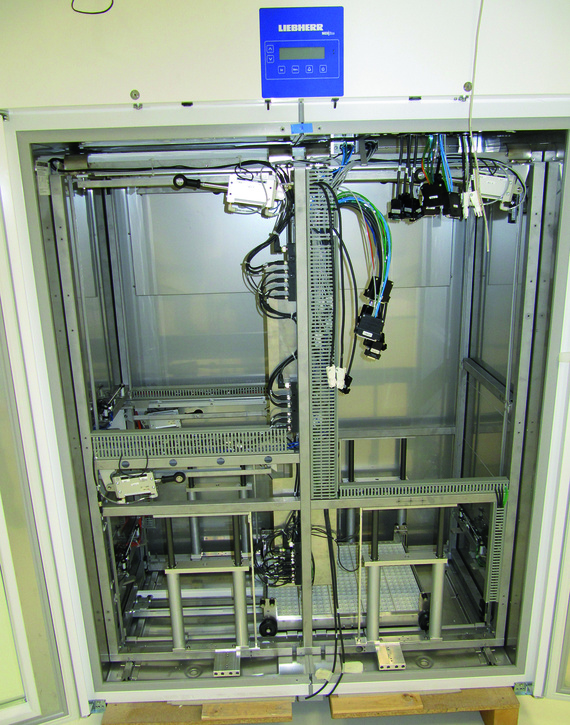

Around 10,000 units of blood are stored and automatically dispensed in this refrigerator made by Loll Feinmechanik GmbH. The units of blood are stored on movable trays and transported to a robot cell for removal via a delivery unit. In order to achieve good space utilisation, a carriage rotation system was developed with 21 carriages that circulate in the refrigerator. drylin linear guides, igubal rod ends and iglidur plain bearings are used to minimise maintenance and corrosion at the bearing points. igus energy chains are also used.Profile

- What was needed: drylin N low-profile guide systems, drylin Q square guides, iglidur plain bearings, igubal spherical bearings, Zipper e-chains

- Requirements: As condensation can occur locally in the refrigerator, lubricating greases had to be avoided to implement the bearings. In addition to this, the aim was to minimise maintenance requirements and ensure silent movement.

- Industry: medical equipment

- Success for the customer: 21 carriages with approx. 500 samples can be stored and processed in the system today. The various rotary and linear bearings enable reliable operation while minimising maintenance work and ensuring high corrosion resistance.

Discover all products for medical technology

Problem

This refrigerator was designed for the storage, organisation and provision of blood samples, which was achieved by well thought-out inner workings. The system is divided into two units: The centrepiece of the system are the numerous movable trays on which the blood samples are located. There is also a delivery unit that transports the trays to a robotic cell for taking a single blood sample.The system, which can accommodate approx. 10,000 blood samples, thus offers an efficient alternative to manual storage systems.

As condensation can occur locally in the refrigerator, lubricating greases had to be avoided when producing the bearing assemblies. In addition to this, the aim was to minimise the maintenance required and ensure quiet movement.

Solution

The carriage rotation system at the heart of the refrigerator enables the largest possible space to be utilised. 21 carriages with approx. 500 samples can be stored in the system. As the carriages can rotate in the refrigerator, the aim was to find bearing components that were as maintenance-free as possible, with both rotary and linear elements being installed.The manufacturer opted for flat and cost-effective drylin N low-profile guide systems, torsion-resistant and flexible drylin Q square guides (drylin Q-10 as indexing shaft) as well as iglidur-G plain bearings, igubal rod ends, iglidur liner and particularly user-friendly zipper e-chains (Series 09).

In particular, the systems solved the problems of maintenance and corrosion resistance in the facility.